Materials & Applications

The Right Tools for the Right JobsHigh Performance & Engineering Materials

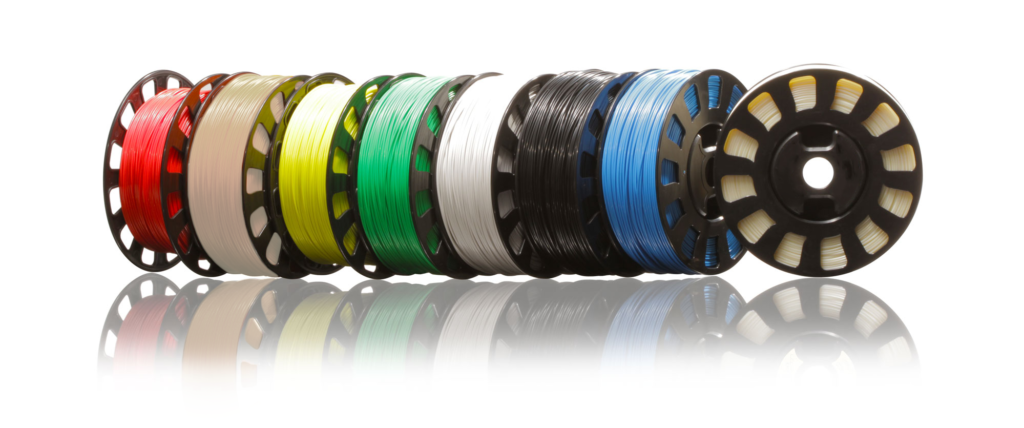

ABS

Acrylonitrile Butadiene Styrene (ABS) is used by 3D FDM or FFF printers and comes in the form of a long filament wound around a spool. Operating the 3D printer is fairly simple: the ABS strand is guided into an extrusion head or extruder that heats the ABS plastic to its melting point in order to liquefy it.

PLA

High level of strength, Low moisture absorption

BVOH

Water-soluble, Supports heavy prints, Nontoxic, Odorless

BVOH

Water-soluble, Supports heavy prints, Nontoxic, Odorless

PA6/66

Heat Resistant up to 180° C, Chemical Resistant, Mechanical Strength

PETG

High printing speed, Thermal resistant, Minimal Shrinkage, Odorless

ProHT

Heat resistance up to 115 °C, Low warping, Food Safe, Matte Finish

HI-TEMP

Heat Resistance up to 160 °C, Appealing Matte Finish, Food Safe

FILAMENT

FILAMENT

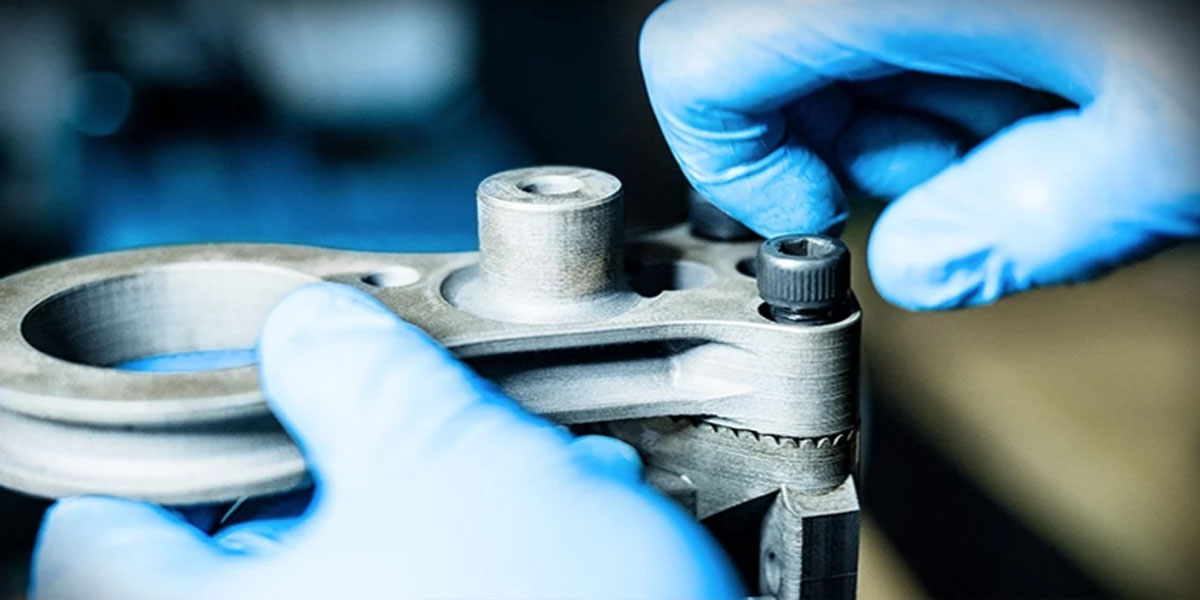

Carbon Fiber

Carbon Fiber is Markforged’s unique, ultra-high-strength Continuous Fiber — when laid into a Composite Base material like Onyx, it can yield parts as strong as 6061-T6 Aluminum. It’s extremely stiff and strong, and can be automatically laid down in a wide variety of geometries by Markforged 3D printers.

Aramid Fiber (Kevlar®)

Aramid Fiber is a Kevlar® based, specialized Continuous Fiber known for its energy absorption and extreme toughness. When laid into Onyx or another Composite Base material, it yields extremely impact-resistant parts that are nearly immune to catastrophic failure (fracture). It’s perfect for use in parts that are in demanding environments or are subject to repetitive loading.

HSHT Fiberglass

Thermally resistant Continuous Fiber for strong parts in high-temperature environments

Fiberglass

Fiberglass is Markforged’s entry-level Continuous Fiber —a material capable of yielding parts 10x stronger than ABS when laid into a Composite Base material like Onyx. Fiberglass is the flagship material of the Onyx Pro and X5 and printable on the Mark Two and X7, providing a more affordable alternative to Carbon Fiber.

Onyx

Micro carbon fiber filled nylon that forms the foundation of Markforged composite parts

Onyx FR

Certified UL 94 V-0 rated flame-retardant micro carbon fiber filled nylon

ProHT

Heat resistance up to 115 °C, Low warping, Food Safe, Matte Finish

HI-TEMP

Heat Resistance up to 160 °C, Appealing Matte Finish, Food Safe

FILAMENT

FILAMENT

ABS

Acrylonitrile Butadiene Styrene (ABS) is used by 3D FDM or FFF printers and comes in the form of a long filament wound around a spool. Operating the 3D printer is fairly simple: the ABS strand is guided into an extrusion head or extruder that heats the ABS plastic to its melting point in order to liquefy it.

PEEK

PEEK (Polyetheretherketone) is considered as one of the world’s highest performing engineering thermoplastics, offering exceptional chemical resistance and excellent mechanical properties at high temperatures.

PEKK

PEEK (Polyetheretherketone) is considered as one of the world’s highest performing engineering thermoplastics, offering exceptional chemical resistance and excellent mechanical properties at high temperatures.

ULTEM(PEI)

ULTEM™ 1010 resin is an amorphous, transparent polyetherimide plastic offering enhanced flow and a glass transition temperature (Tg) of 215°C.

ULTEM™ 9085 resin offers the ability to create parts with excellent properties at elevated temperatures due to a glass transition temperature (Tg) of 186°C.

PPSU

These are moldable plastics often used in rapid prototyping and rapid manufacturing (direct digital manufacturing) applications. Polyphenylsulfone is heat and chemical-resistant suited for automotive, aerospace, and plumbing applications

Nylon

Nylon exhibits mechanical properties comparable to ABS (another widely used material in traditional & additive manufacturing). ABS is defined by its strength but Nylon’s resistance to wear and fatigue makes it superior for applications requiring such properties.

PC

Polycarbonates used in engineering are strong, tough materials, and some grades are optically transparent. They are easily worked, molded, and thermoformed.

TPU

Thermoplastic Polyurethane or TPU is referred to as the bridge between rubbers and plastics. The material appears rubber-like, which means it can be extremely flexible, durable and smooth to the touch.

Carbon Fiber

Carbon fiber filaments use tiny fibers that are infused into a base material to improve the properties of that material. These fibers are extremely strong and cause the filament to increase in strength and stiffness. This also means that the 3D printed parts will be much lighter and more dimensionally stable

Glass Fiber

Fiberglass is mostly melted glass that has been pulled into long, thin strands and then glued together using a crosshatch pattern and resin for added strength. It has quite a few unique benefits.

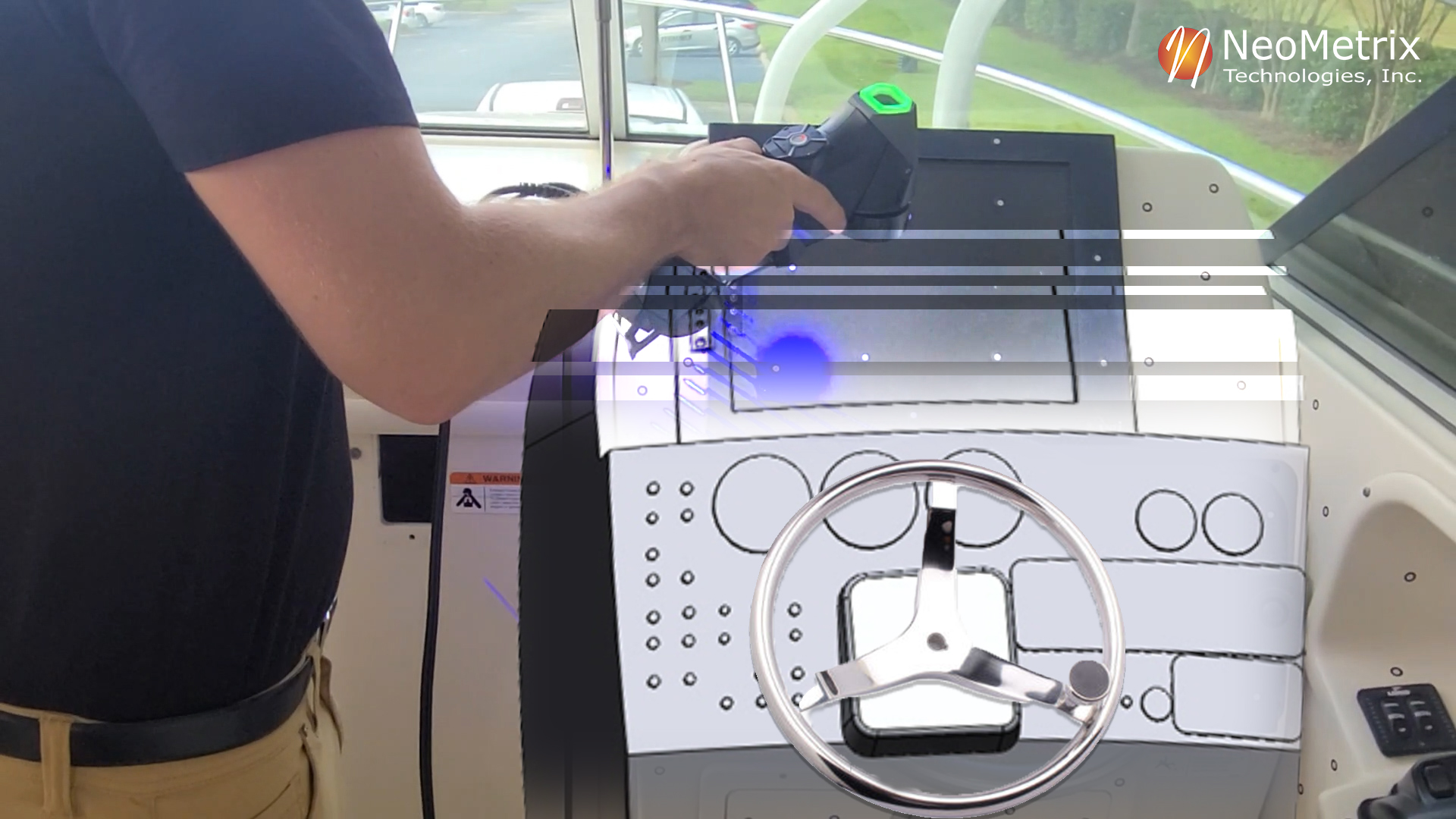

INDUSTRIAL APPLICATIONS

3D printing is a cost effective method to analyze your part designs before committing to the high cost of tooling development or the machining of production parts. NeoMetrix utilizes MultiJet, PolyJet, CFF, FDM, SLS and SLA technologies for 3D printing. Our 3D printers can produce parts in a variety of different photopolymer materials. Ultra fine layer thickness create accurate, clean, smooth and highly detailed 3-dimensional models for a variety of applications:

- Rapid Prototyping

- Concept Modeling

- Silicone Molding

- Additive Manufacturing

- Rapid Tooling

| TOP ADDITIVE MANUFACTURING INDUSTRIES |

AEROSPACE

ART/SCULPTURE

AUTOMOTIVE

MANUFACTURING

MARINE

MEDICAL