The Next Level of Automated Production

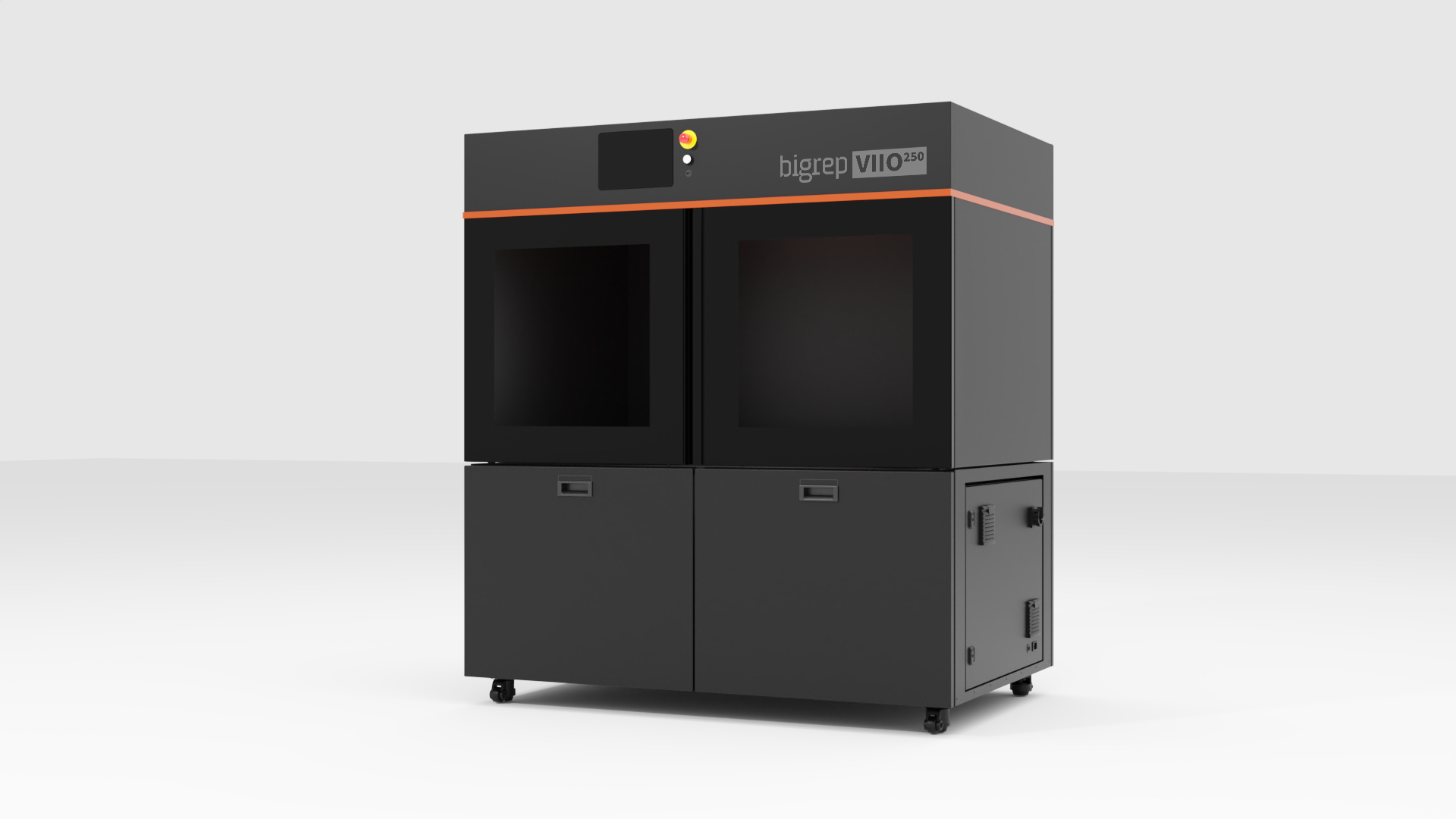

The large-scale BigRep VIIO 250 is a fully automated 3D printer engineered for reliable, continuous industrial manufacturing. Equipped with breakthrough automation features like Relay Mode for backup extruder function, auto print bed calibration, auto-sequential printing, and the Infinity Box automated filament handler, the VIIO 250 maximizes machine efficiency. Experience high-efficiency, cost-effective production with the VIIO 250, allowing you to print more quality parts in less time, reduce energy consumption, and focus on what truly matters.

► Large build volume (1000 mm x 500 mm x 500mm)

► Max Print speed of up to 500 mm/s

► Layer Height of 0.2mm, 0.3mm, 0.5mm (Other layer heights supported through slicer software)

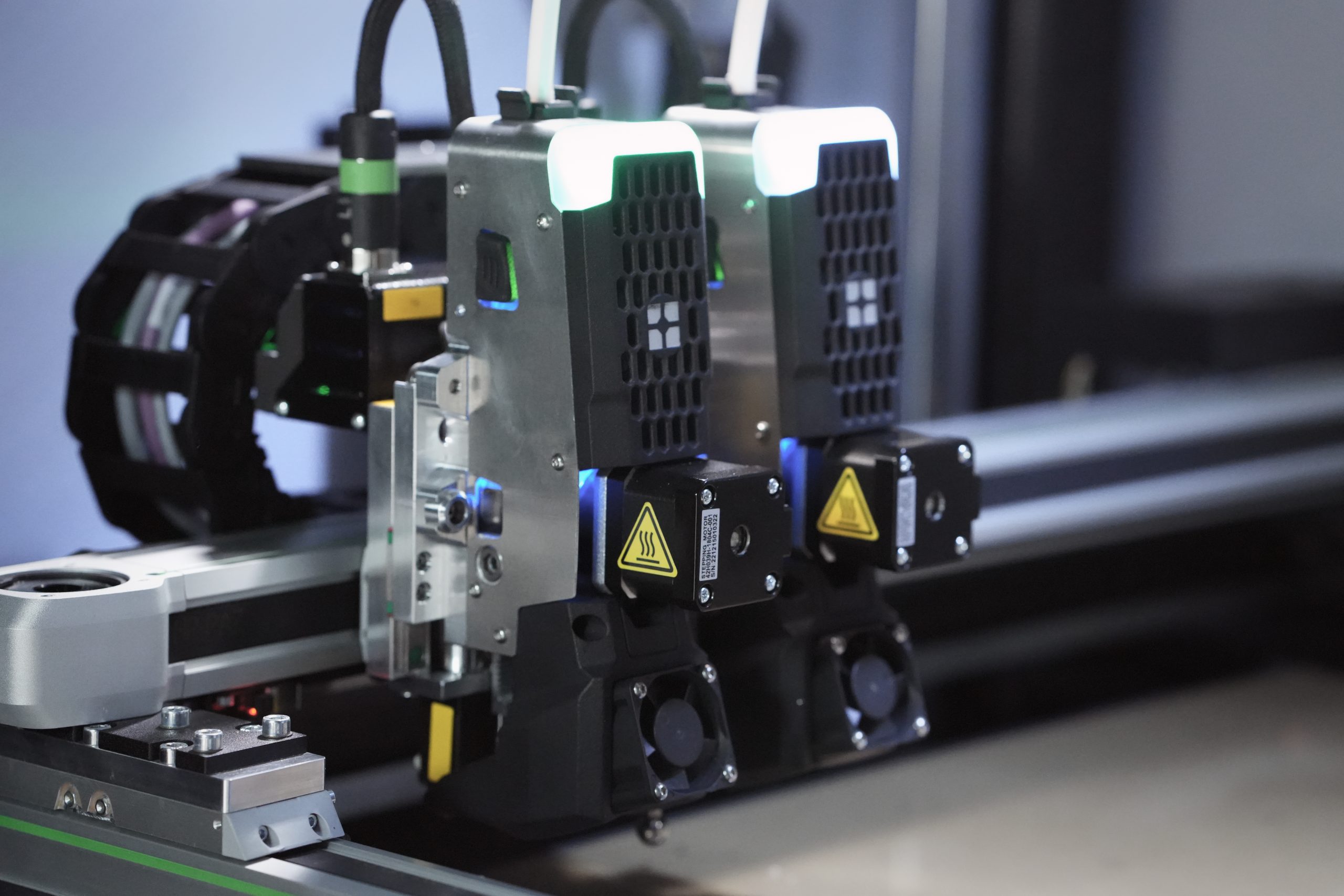

► Dual Smart Manufacturing Extruders (SMX) : Nozzles- Tungsten carbide (0.4mm, 0.6mm) or polycrystalline diamond (1.0mm)

► High-Temperature Access: Extruder: Up to 350°C – Print Bed Temp: Up to 120°C – Chamber Temp: 30-50°C

See How BigRep VIIO 250 Transforms Industrial 3D Printing!

FEATURES

HUGE HIGH-RESOLUTION PARTS

LARGE-SCALE 3D PRINTING

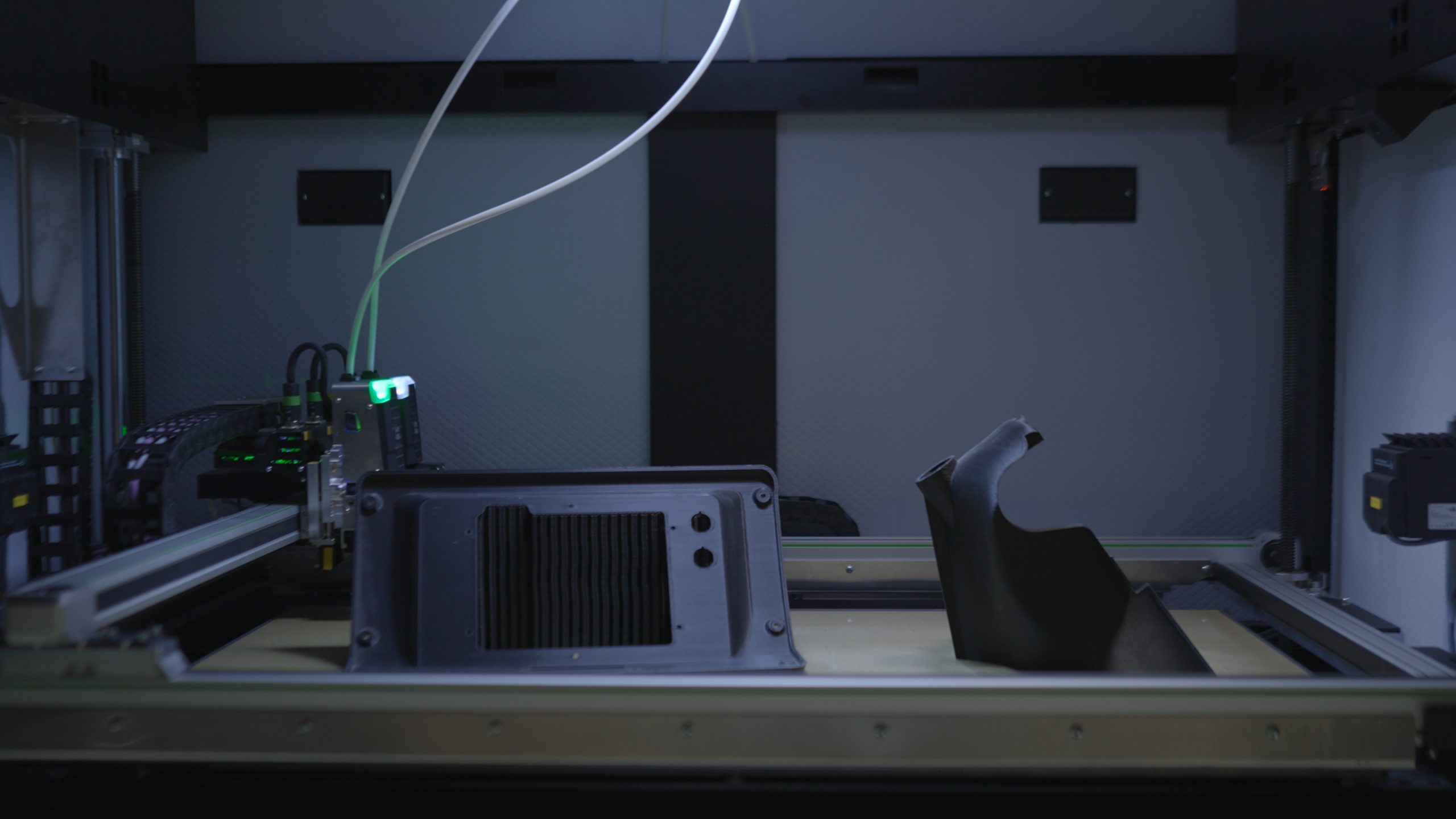

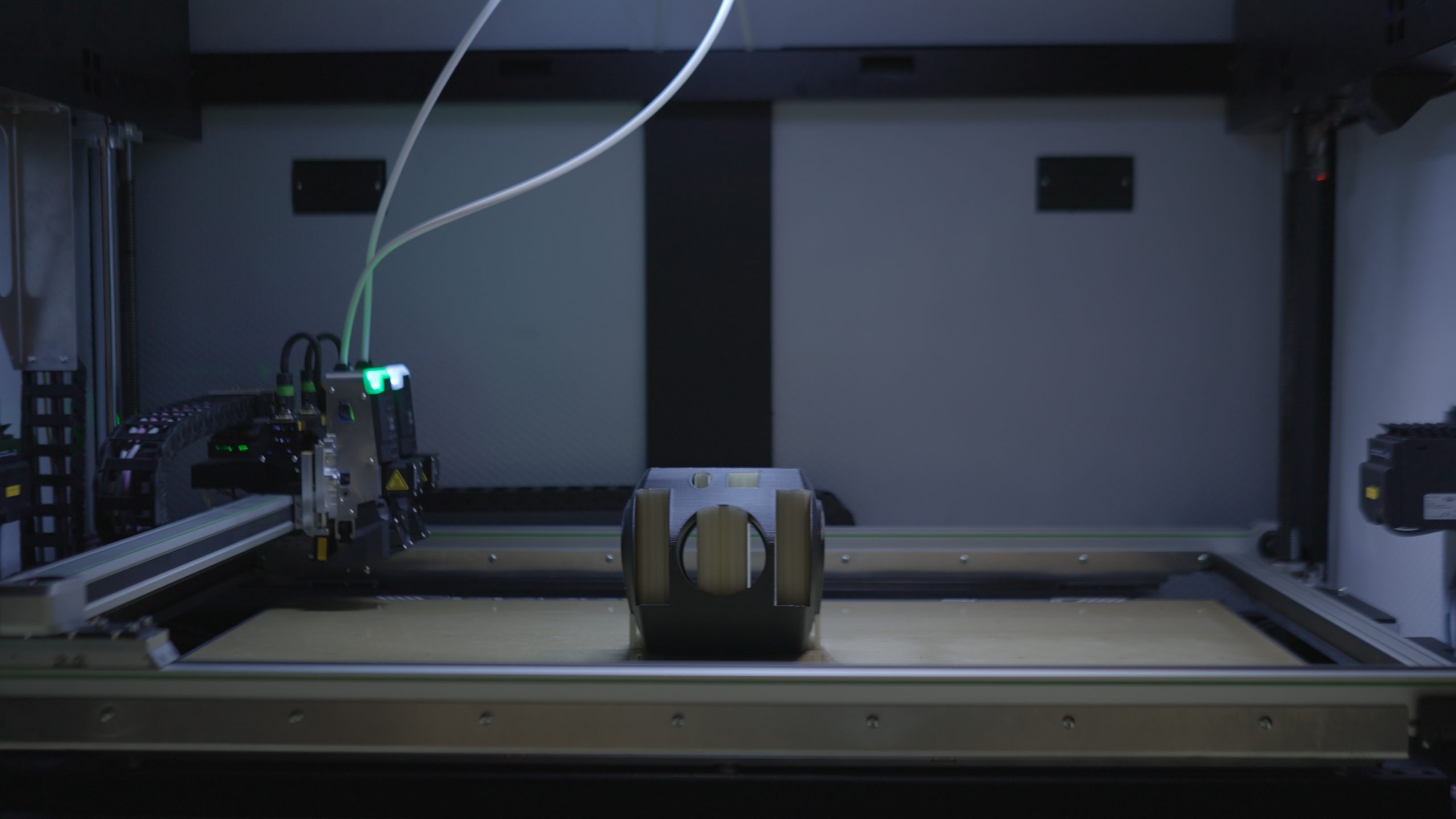

Achieve maximum geometric accuracy with VIIO 250’s actively temperature-controlled build chamber of 1000 mm x 500 mm x 500mm (build volume of 250 liters) that heats up to 50°C. The compact design offers large-format printing capabilities in a robust, sleek frame that fits in any workspace.

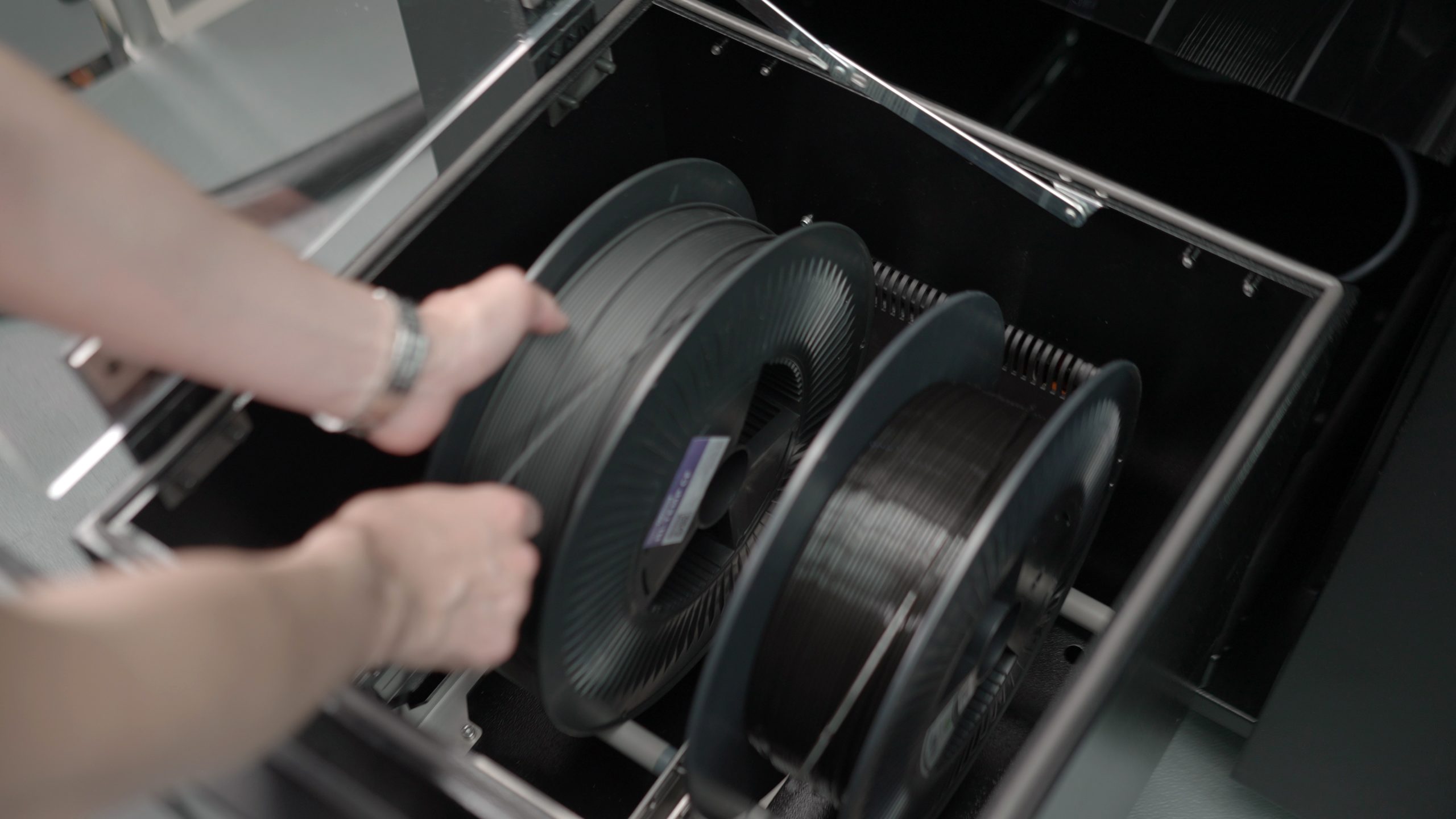

24/7 AUTOMATION

Enabling unattended production, the VIIO 250 comes with groundbreaking fully automated features: the Infinity Box and Relay Mode. The Infinity Box loads new filament automatically when the material runs out during a print job without any intervention.

PRECISE PRINTS WITH ANY MATERIAL

With a print bed temperature of up to 120°C, the VIIO 250 maintains uniform heat distribution for consistently robust parts. The print bed’s temperature also enables strong part adhesion thanks to the flexible SWITCHPLATE® removeable print bed surface. The heat keeps the print fixed in place, and when the printer cools down, you can easily pop the part off in seconds.

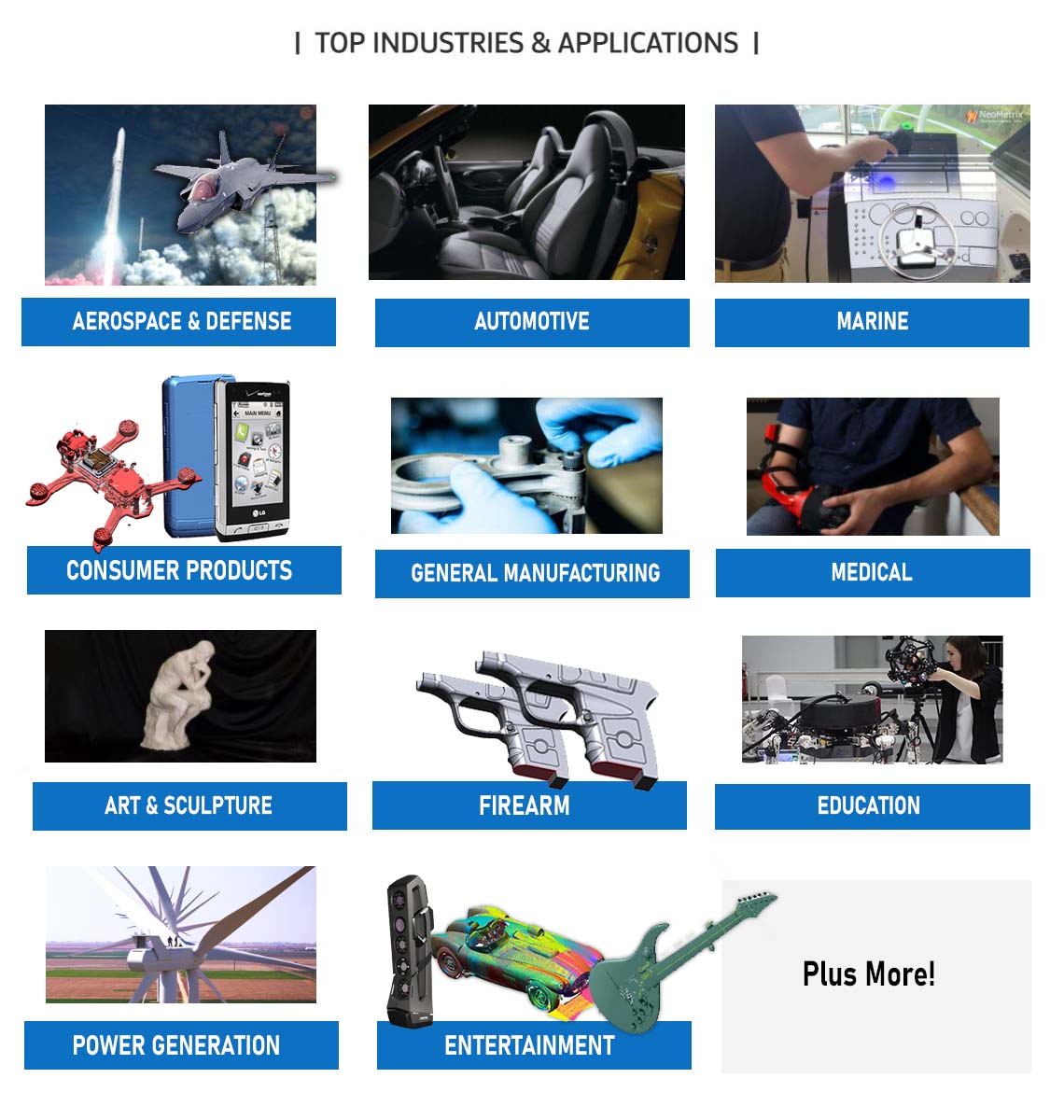

ADVANCED MATERIALS FOR INDUSTRIAL APPLICATIONS

The heart of all BigRep machines is the material system that’s open for innovation. Print with any compatible filament of your choice – BigRep’s or a 3rd party’s – and unlock new applications with the VIIO 250. BigRep’s portfolio of industrial-grade 3D printer filaments ranges from affordable, general-use materials to technical materials for demanding industrial applications.

Includes:

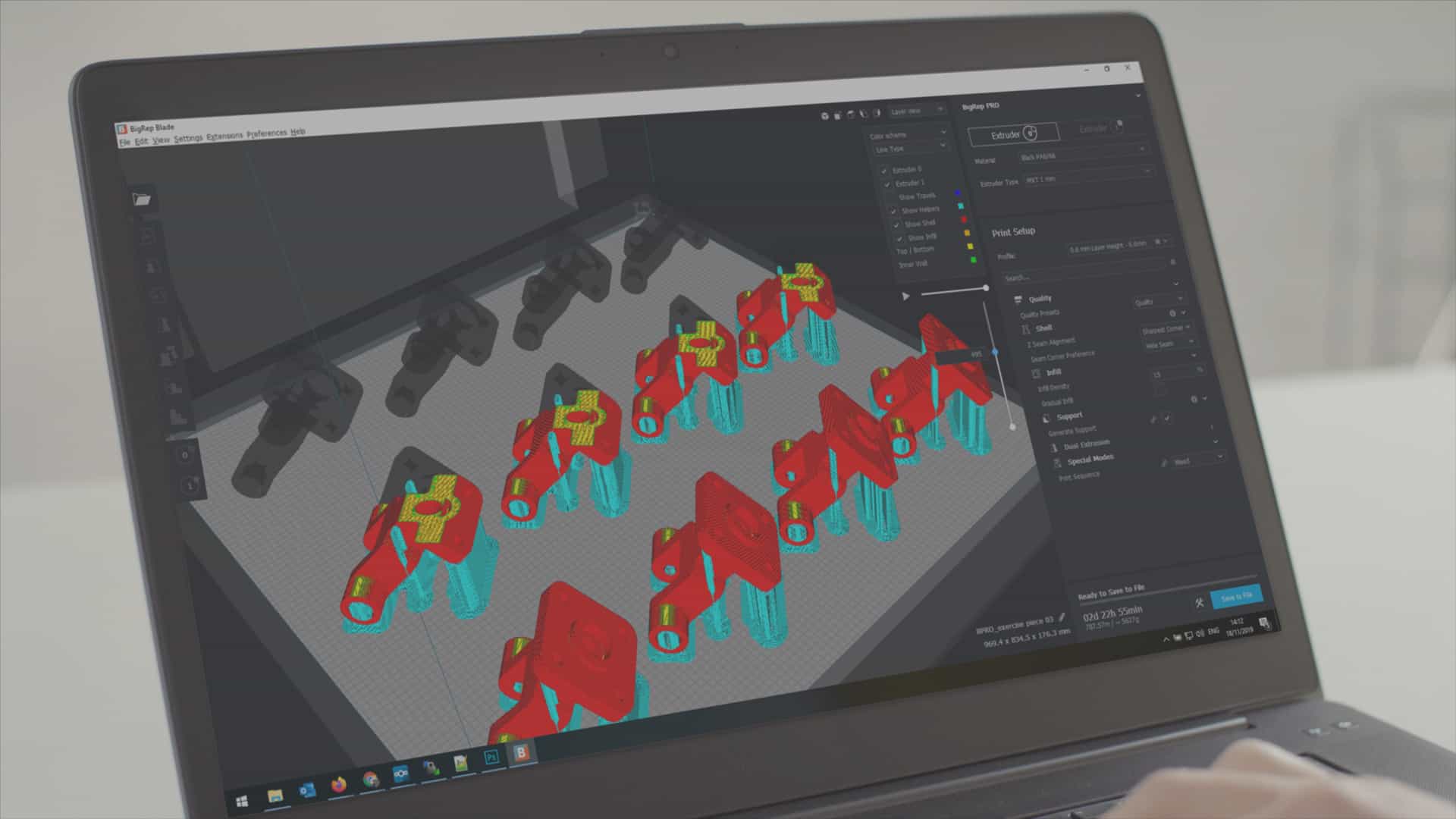

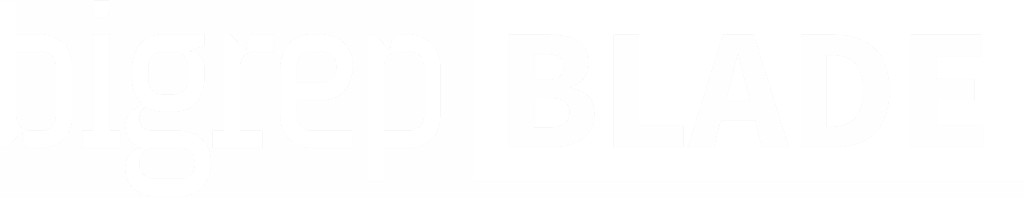

A SMART 3D SLICER FOR INDUSTRIAL APPLICATIONS

Speak With an Expert!

Fill out this our quick contact form or call us today- (888) 696-7226

BigRep VIIO 250

NEXT LEVEL OF AUTOMATED PRODUCTION

-

-

-

3D Print in Full Scale

-

Boost Productivity

-

Cut Your Costs

-

Print Parts in a Variety of Engineering Grade Materials

-

-

TECHNICAL SPECIFICATIONS

| Build volume | (1000mm x 500mm x 500mm ) | |

| Print speed | Up to 500 mm/s | |

| Layer height | 0.2mm, 0.3mm, 0.5mm (Other layer heights supported through slicer software) | |

| Extruder | Dual Smart Manufacturing Extruders (SMX) | |

| Nozzle Type | Tungsten carbide (0.4mm, 0.6mm) or polycrystalline diamond (1.0mm) | |

| Extruder Temp | Max Up to 350°C | |

| Print Bed Temp | Up to 120°C | |

| Printing technology | FFF- Fused-Filament-Fabrication (FDM) | |

| Certified materials | ABS, ASA, PA12 CF, and PA6/66, BigRep HI-TEMP, BigRep HI-TEMP CF, BigRep PETG, BigRep PLA, BigRep PLX, BigRep PRO HT, BigRep TPU 98A Open for use of 3rd party materials |

|

| Size | 1634mm x 1069mm x 1829mm | |

| Power | 208-240 V, 50/60Hz, 16 A | |

| Safety Certifications | SWITCHPLATE prime, SWITCHPLATE select | |