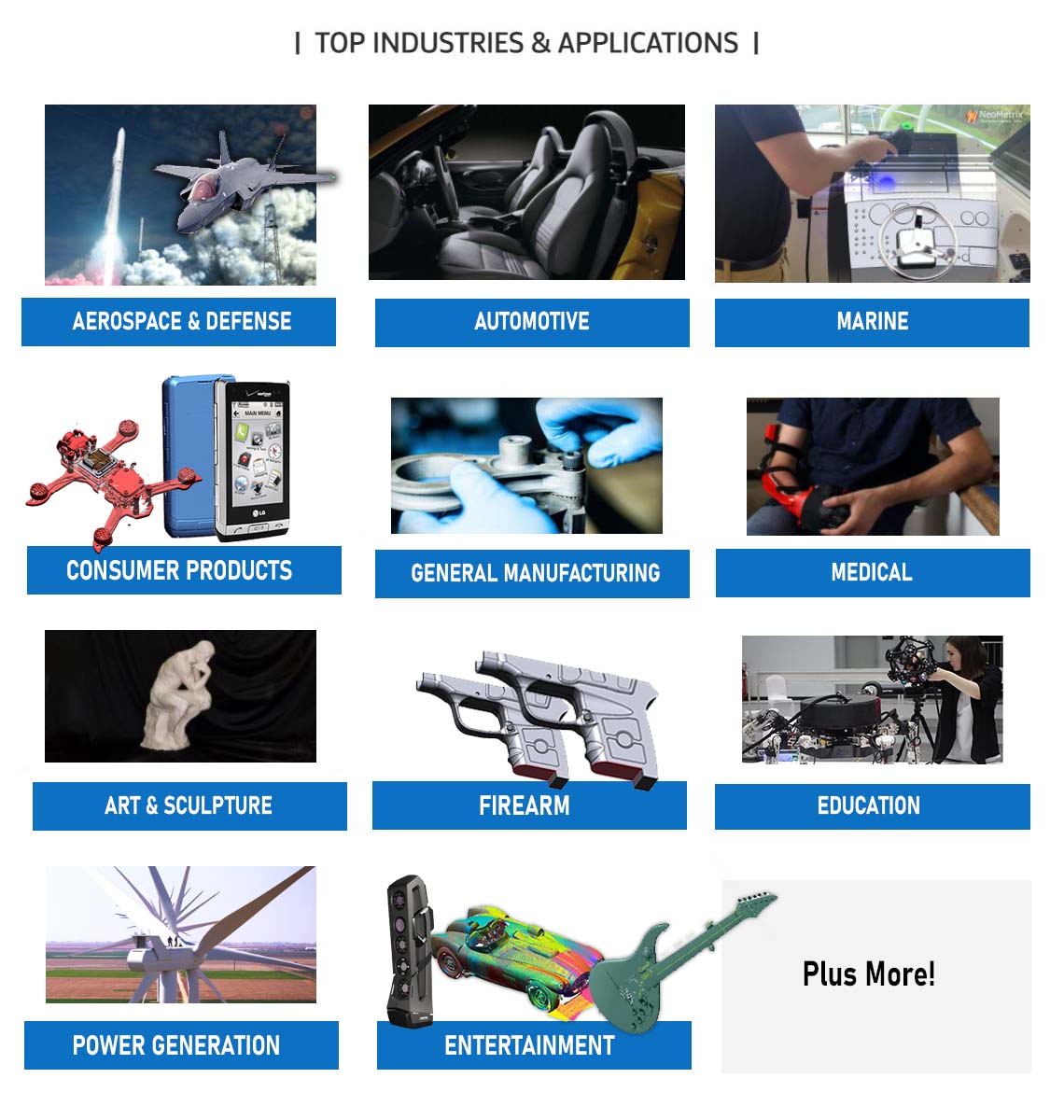

Mark Two – Continuous Fiber Composite 3D Printer built to revolutionize your manufacturing operation

A leading way to make aluminum-strength parts on your desktop — the Mark Two carbon fiber composite 3D printer enables engineers to generate massive value for their business.

► Build Volume (320 mm x 132 mm x 154 mm)

► Print speed of up to —mm/s | —mm/s²

► Layer Resolution of 100 μm – 200 μm

► Printing Process Continuous Fiber Reinforcement (CFR)

► Access to High-Strength Materials – Onyx®, Nylon, Smooth TPU 95A, Precise, PLA, Carbon Fiber, Fiberglass, Aramid Fiber (Kevlar®), HSHT Fiberglass

FEATURES

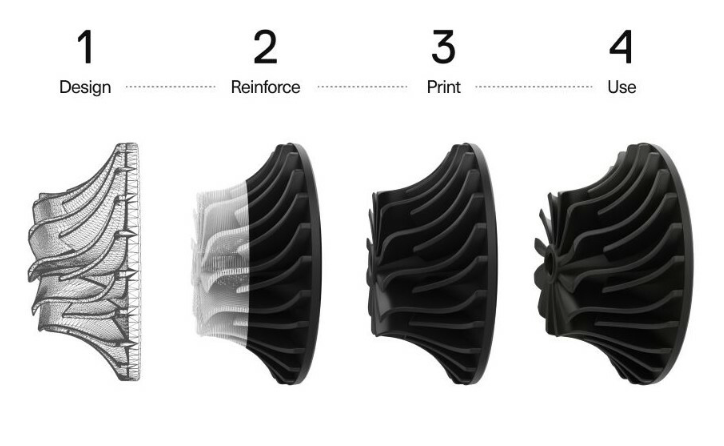

SPECIALIZED PRINTING TECHNOLOGY

CARBON FIBER STRENGTH

Print Continuous Carbon Fiber reinforced parts on your desktop – stiff, strong, extremely durable, and capable of replacing machined aluminum.

HIGH-ACCURACY RESULTS

BUILT TO LAST

A unibody aluminum chassis and precision-machined components deliver lights-out reliability over thousands of print hours.

FOR BEGINNERS & ADVANCED

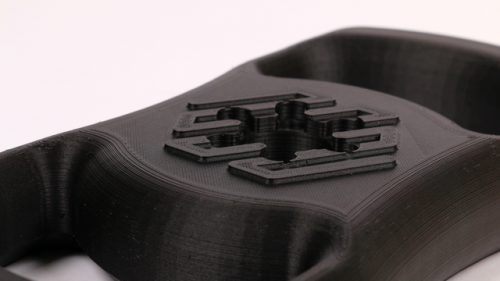

PRECISE AND BEAUTIFUL PARTS

Print precise parts with best-in-class surface finish thanks to Onyx, Markforged’s extremely versatile micro carbon fiber filled nylon material.

SEMI-AUTOMATIC PRINT BED

FLEET MANAGEMENT

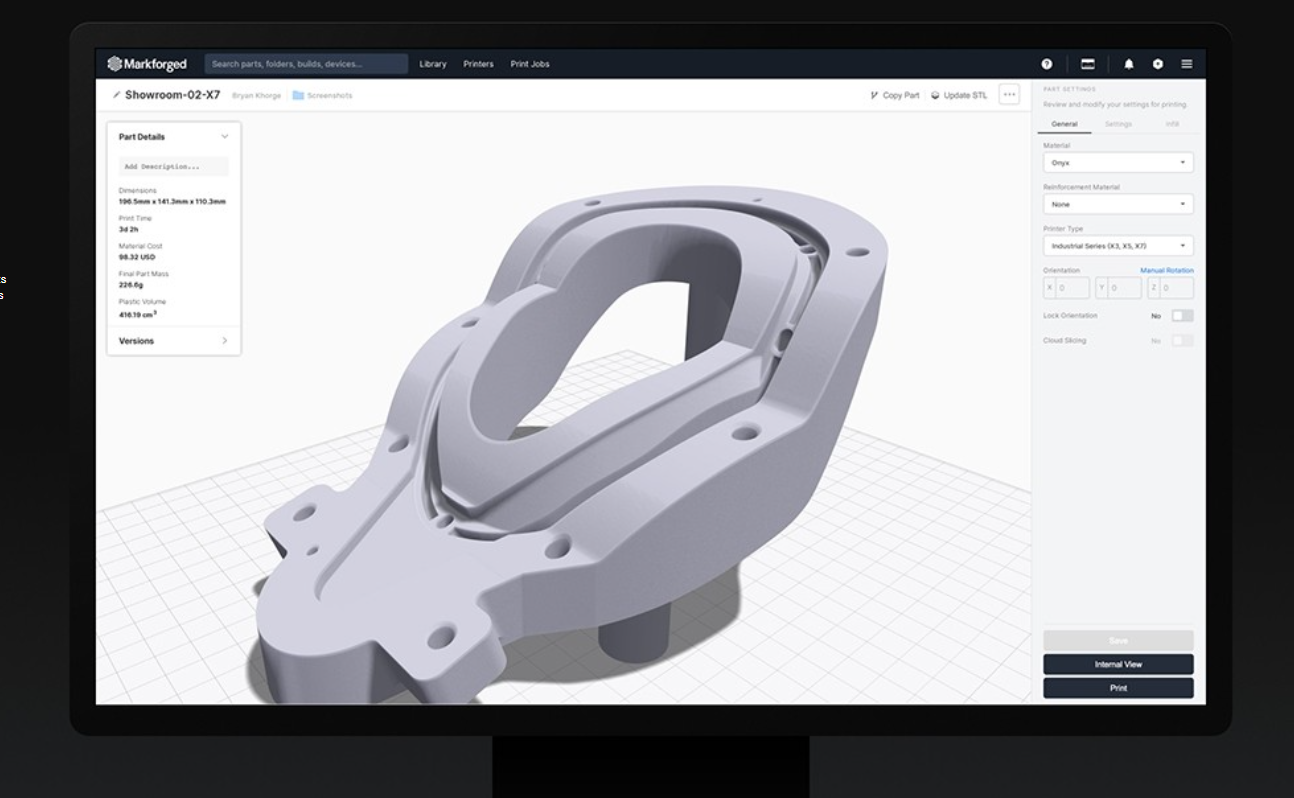

Including the world’s most advanced 3D printing software- Eiger. Designed from the ground up to make manufacturing simpler, Eiger enables you to print plastic, metal and composite parts straight from your browser. print plastic, metal and composite parts straight from your browser.

3D Print Strong Continous CF Parts on the Mark Two

Producing Electronic Enclosures on Industrial 3D Printers

The power of Continuous Carbon Fiber at your fingertips.

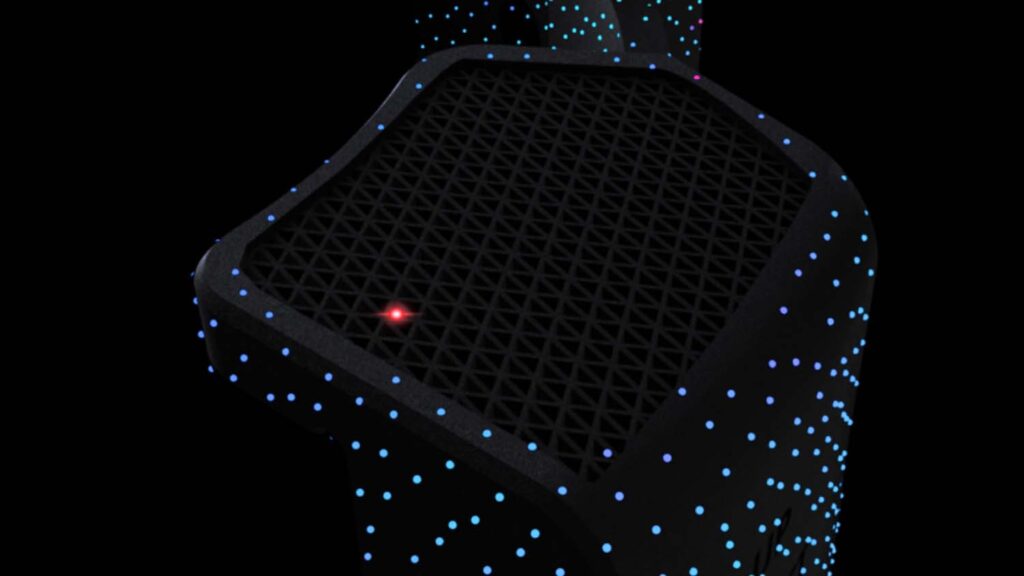

The Mark Two specializes in fiber reinforcement system that enables you to lay down continuous fiber into parts. Markforged composite printers are uniquely capable of printing four types continuous fiber-reinforced parts. Right from your desktop!

Eiger Cloud– Design, Slice, and Print Directly From Your Browser

3D Printing Software Meets Production Management

Simulate & Inspect- Optimize Part Performance and get Reporting

Speak With an Expert!

Fill out this our quick contact form or call us today- (888) 696-7226

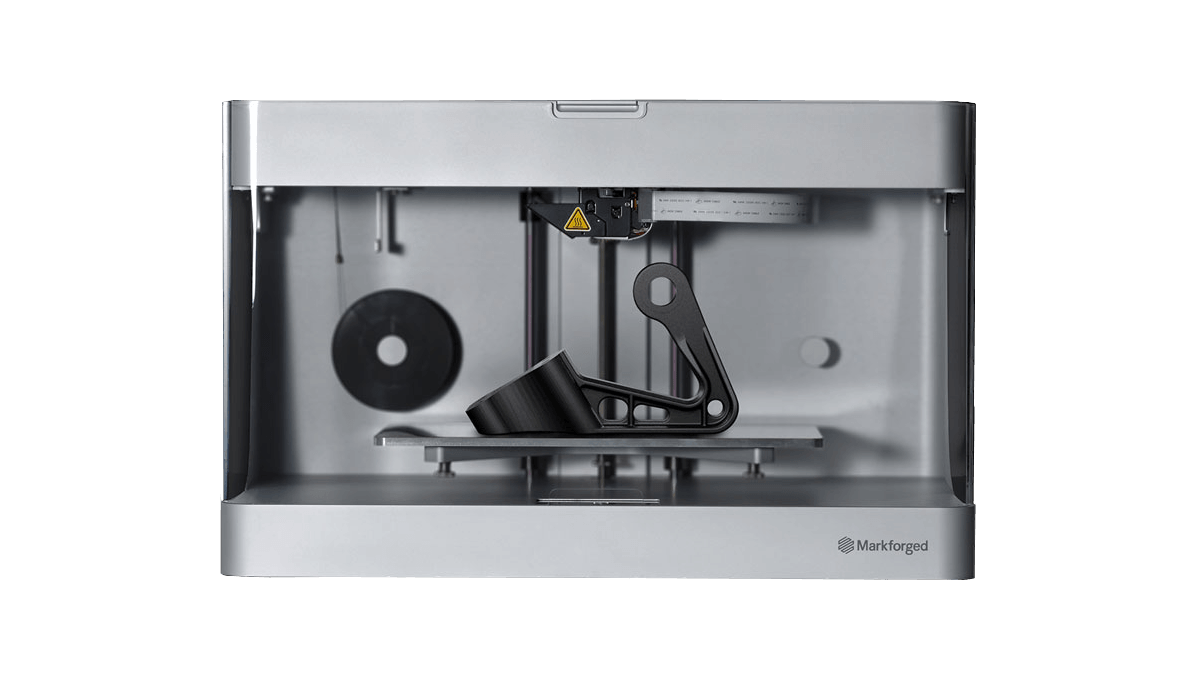

Markforged X7

The turnkey industrial carbon fiber 3D printer for many types of functional parts.

- Carbon Fiber Stregnth

- Functional Parts of All Types

- Industrial Reliability and Accuracy

TECHNICAL SPECIFICATIONS

| Build volume | (330 mm x 270 mm x 200 mm) | |

| Print speed | — mm/s max. , TURBO MODE: — mm/s max. | |

| Z Layer Resolution | 100 μm default, 50 μm minimum, 250 µm maximum | |

| Laser | In-process inspection, active print calibration, bed leveling | |

| Nozzle Temp | Max — | |

| Print Bed Temp | Max. — | |

| Extrusion System | Second-generation extruder, out-of-plastic and out-of-fiber detection | |

| Plastics Available | Onyx, Onyx FR, Onyx ESD, Nylon White, P-PLA, S-TPU | |

| Fibers Available | Carbon Fiber, Carbon Fiber FR, Fiberglass, Aramid Fiber (Kevlar®), HSHT Fiberglass |

|

| Size & Weight | 584 mm x 483 mm x 914 mm , 106 lbs | |

| Power | 100–240 VAC, 150 W (2 A peak) | |

| Software | Eiger Cloud(Included), Security, Blacksmith(Additional Purchase) | |