Markforged 3D Printing Systems

Rapid Prototyping, Concept Modeling & Additive Manufacturing

Industrial grade, exceptional accuracy, reliability and repeatability. The go-to solution for manufacturing tooling.

The DNA of the Industrial Series in a package that fits on your desktop. The Desktop line won the enterprise printer of the year in 2017.

Go from design to fully functional metal parts in under 24 hours — the Metal X is an end-to-end manufacturing solution.

NEW | Markforged FX10

Next-Gen 3D Printer for Innovation & Production

Print continuous carbon fiber reinforced parts for a wide range of factory floor applications — deliver strong, accurate parts for every print.

Enter your info to receive updates about the FX20 3D Printer!

Markforged FX20

Engineered from the ground up for unparalleled performance and consistency, FX20 brings our patented composite technology to a larger scale and scope of applications and industries. Capable of printing high-temperature thermoplastics with continuous carbon fiber, this beast of a machine delivers high-strength, aerospace-grade parts at the click of a button.

Enter your info to receive updates about the FX20 3D Printer!

Schedule a FREE Consultation Today!

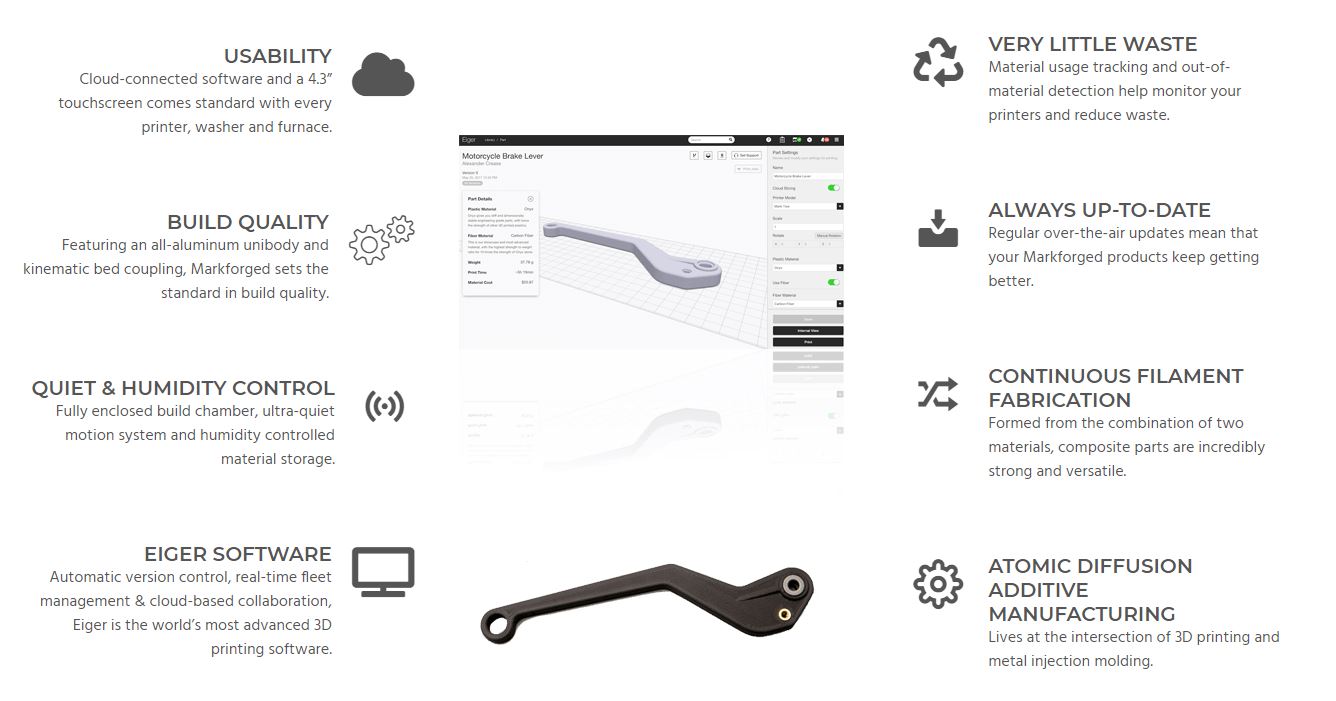

MARKFORGED 3D PRINTER FEATURES

With Markforged, print carbon fiber for parts that are as strong as aluminum and dramatically lighter. For heat tolerance, print with 17-4 Stainless Steel. For anything else, print with Titanium, Aluminum, Kevlar, or one of our 11 other materials to fit any functional application.

Contact Request Form | 3D Printing Equipment

METALS

ONLY AVAILABLE ON METAL X

From stainless steel to superalloys, Markforged offers a full suite of metal 3D printing materials designed to help you manufacture complex parts affordably. Our metal filaments combine the simplicity and safety of FFF printing with the superior properties of advanced metals, bringing metal 3D printing to your benchtop.

ONYX

Already 40% stiffer than ABS, Onyx provides the foundation for Markforged’s 3D printed advanced composites materials. It can be printed on its own or reinforced with any of our four continuous fibers. Nylon mixed with chopped carbon fiber offers a high-strength thermoplastic with excellent heat resistance, surface finish, and chemical resistance.

COMPOSITE

Markforged composite printers use a base plastic matrix reinforced with continuous fibers. Combining the materials during printing yields composite parts far stronger, stiffer, and more robust than conventional 3D printed plastics.