BigRep Materials/Filament

The best materials to suit Large-Scale 3D Printing

ProHT - Easy Printing and Support Removal

BigRep’s ABS material is a classic FFF filament that enables the production of a wide variety of products in large-format additive manufacturing. A familiar automotive manufacturing material now specialized for industrial AM, BigRep ABS is a high-strength filament suitable for mobility and a variety of white-goods and consumer appliances.

MADE FOR: STUDIO G2

ASA- Weather and UV Resistant

Weather and UV Resistant

BigRep ASA is an engineering-grade UV-resistant filament for high-strength and environmentally exposed applications. Designed for industrial and end-use parts, ASA is a strong material with high mechanical resistance, low shrinkage and superior layer adhesion. It is highly suited to applications in automotive, sporting goods, white goods and consumer appliances.

MADE FOR:

PRO , STUDIO G2

PLA- Affordable and Versatile

High level of strength, Low moisture absorption

The strength and stiffness of BigRep PLA makes this filament ideal for demanding industrial production, such as in 3D printing large objects for the architecture or construction fields. BigRep PLA is an easy-to-use filament optimized for producing prototypes and pattern making, for end-use parts to the wide range of tooling applications.

MADE FOR: ONE , PRO , STUDIO G2

PLX- Fast and Reliable

BigRep’s PLX filament is a PLA-derived, general-use bio performance material for open-environment 3D printing. An innovative and robust thermoplastic filament, PLX can print up to 80% faster than a standard PLA material with no modification to the 3D printer at a strength that exceeds the typical mechanical properties of even ABS-printed parts – enabling industrial additive manufacturing in large-format at unprecedented speeds. PLX is incredibly versatile, allowing printer settings to be tuned for either incredible speeds or beautifully smooth surface finishes.

MADE FOR: ONE , PRO , STUDIO G2

HI-TEMP CF- High Temperature Carbon Fiber

Heat Resistance up to 160 °C, Appealing Matte Finish, Food Safe

BigRep’s HI-TEMP CF is a high-strength engineering-grade filament with a high heat deflection temperature. Highly stiff and incredibly durable, the material effectively maintains its form under high heat conditions. Ideal for the thermoforming process, HI-TEMP CF is the perfect match for the production of patterns and molds..

MADE FOR: ONE , PRO , STUDIO G2

BVOH- Advanced Water Soluble Supports

MADE FOR: ONE , PRO , STUDIO G2

HI-TEMP- High Temperature Resistant

High Temperature Resistant

MADE FOR: ONE , PRO , STUDIO G2

PA6/66- Lightweight and Resistant

Lightweight and Resistant

Heat Resistant up to 180° C, Chemical Resistant, Mechanical Strength

It is a light-weight thermoplastic material with high rigidity, and has high resistance to heat and chemicals. Its high compatibility with machining and mechanical strength make it an excellent candidate for most industrial applications, especially in the automotive and aerospace sectors.

PETG- Durable & Impact Resistant

High printing speed, Thermal resistant, Minimal Shrinkage, Odorless

The material is full compatible with all FFF open-build 3D printers, and has been optimized for use on BigRep large-scale machines, for a wide range of applications.

MADE FOR: ONE , PRO , STUDIO G2

ABS - Strong & Versatile

BigRep’s ABS material is a classic FFF filament that enables the production of a wide variety of products in large-format additive manufacturing. A familiar automotive manufacturing material now specialized for industrial AM, BigRep ABS is a high-strength filament suitable for mobility and a variety of white-goods and consumer appliances.

MADE FOR: STUDIO G2

TPU- Flexible and Versitle

Heat resistance up to 115 °C, Low warping, Food Safe, Matte Finish

MADE FOR: ONE , PRO , STUDIO G2

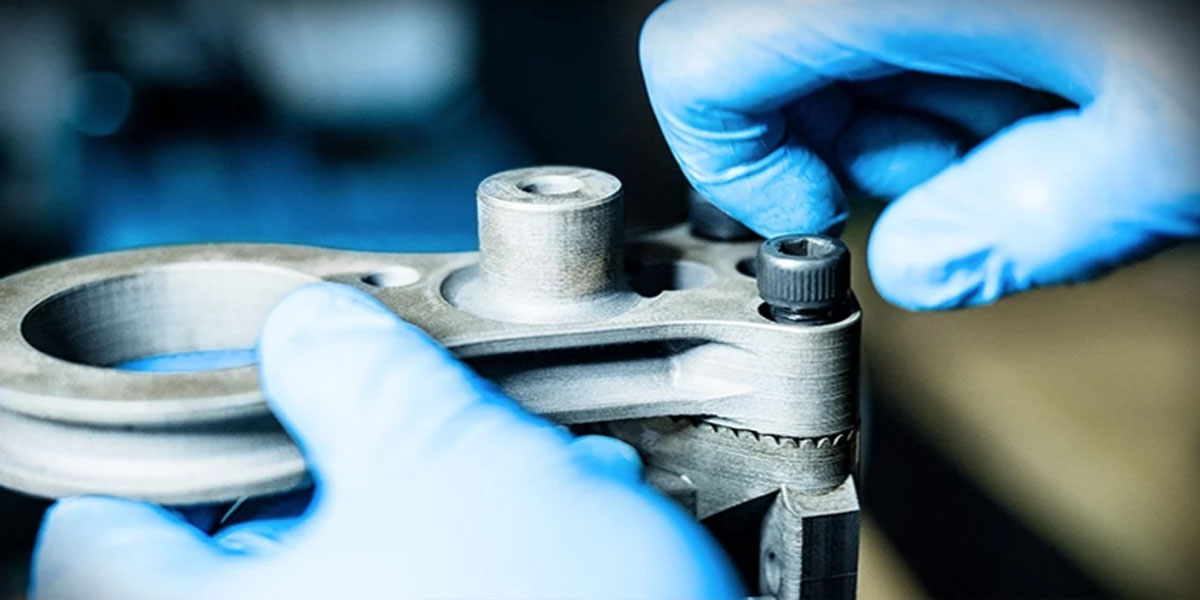

MEET ANY INDUSTRIAL APPLICATIONS

- Rapid Prototyping

- Concept Modeling

- Silicone Molding

- Additive Manufacturing

- Rapid Tooling

| TOP ADDITIVE MANUFACTURING INDUSTRIES |

AEROSPACE

ART/SCULPTURE

AUTOMOTIVE

MANUFACTURING

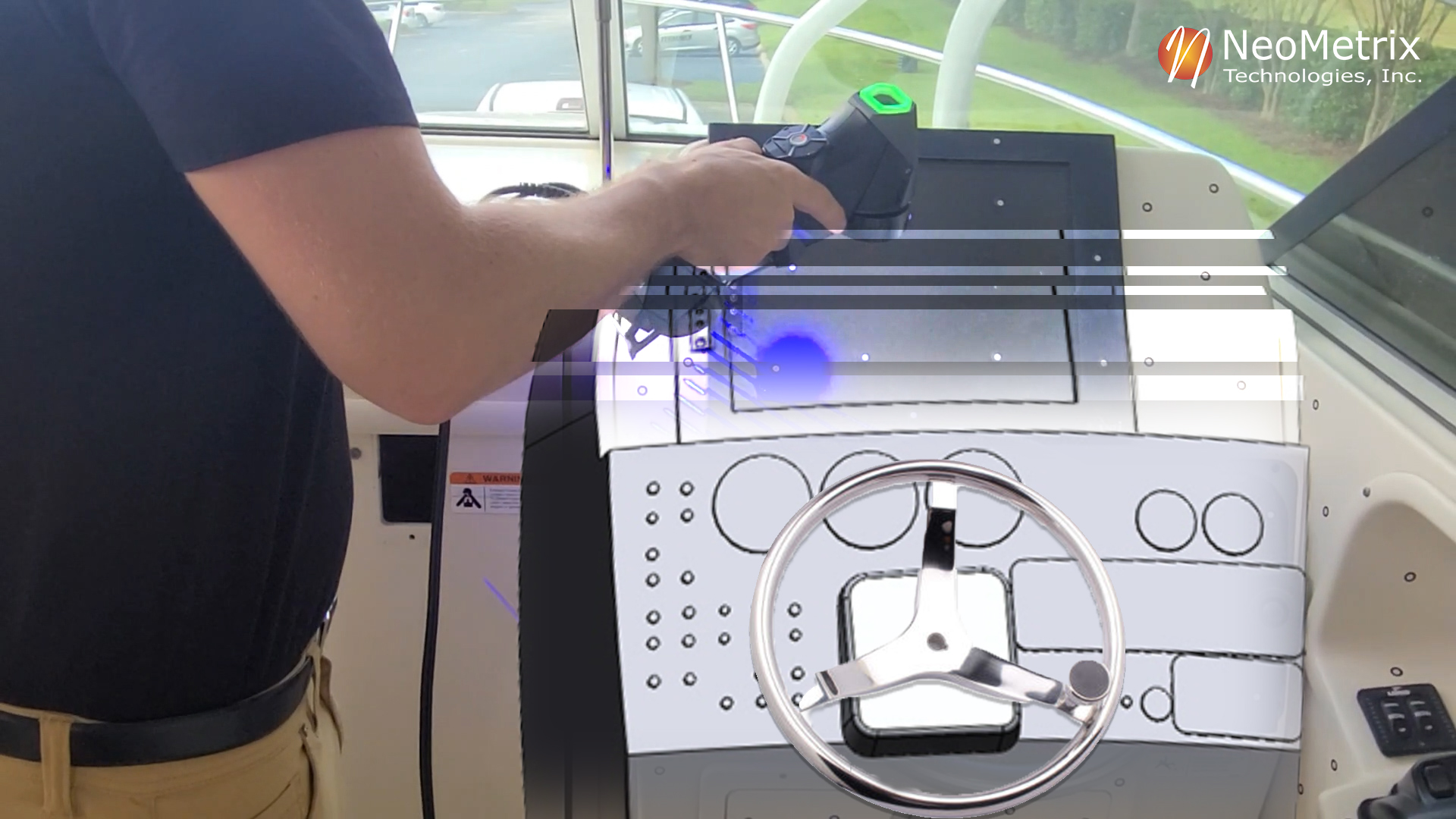

MARINE

MEDICAL