Large Build Volume Industrial 3D Printer

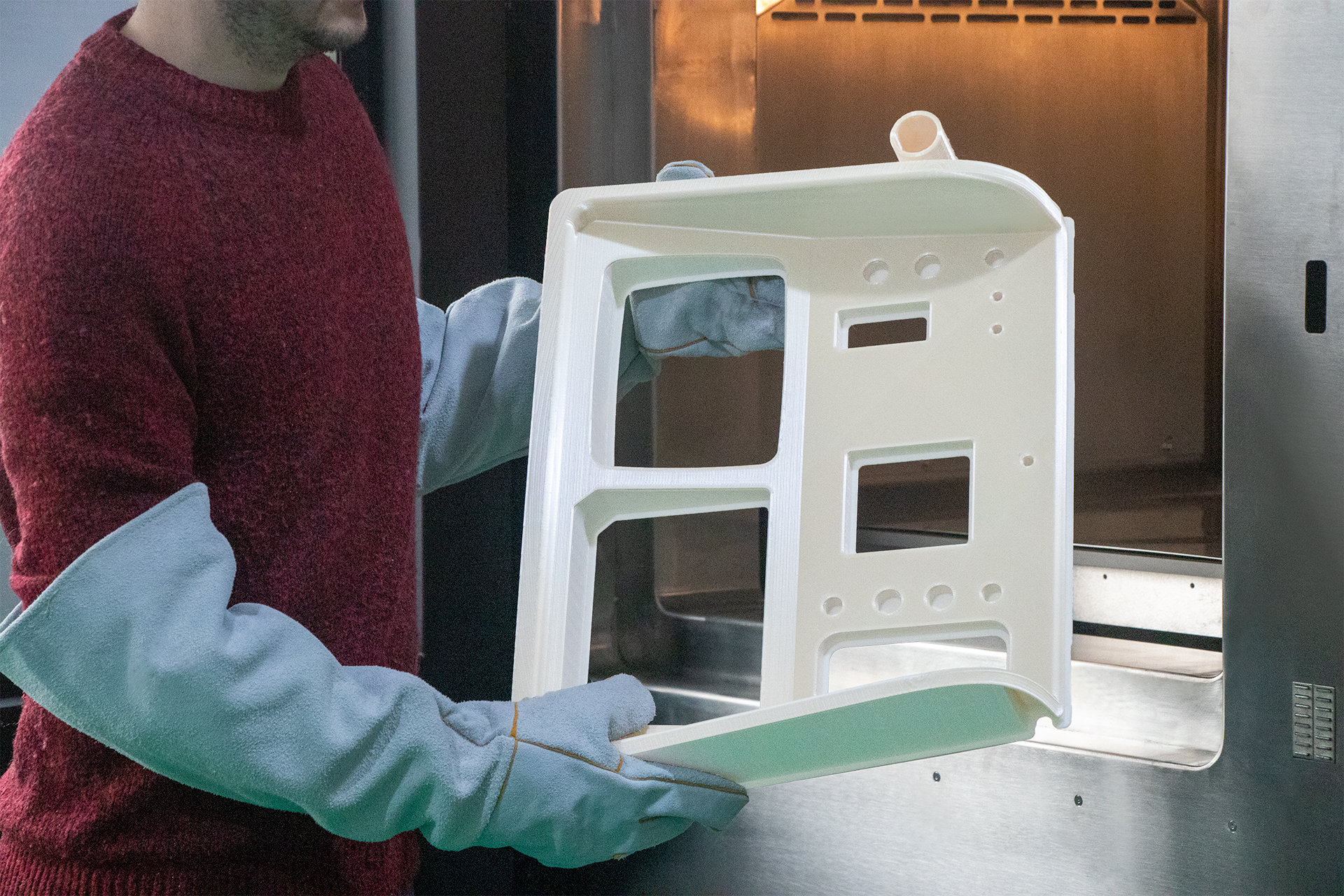

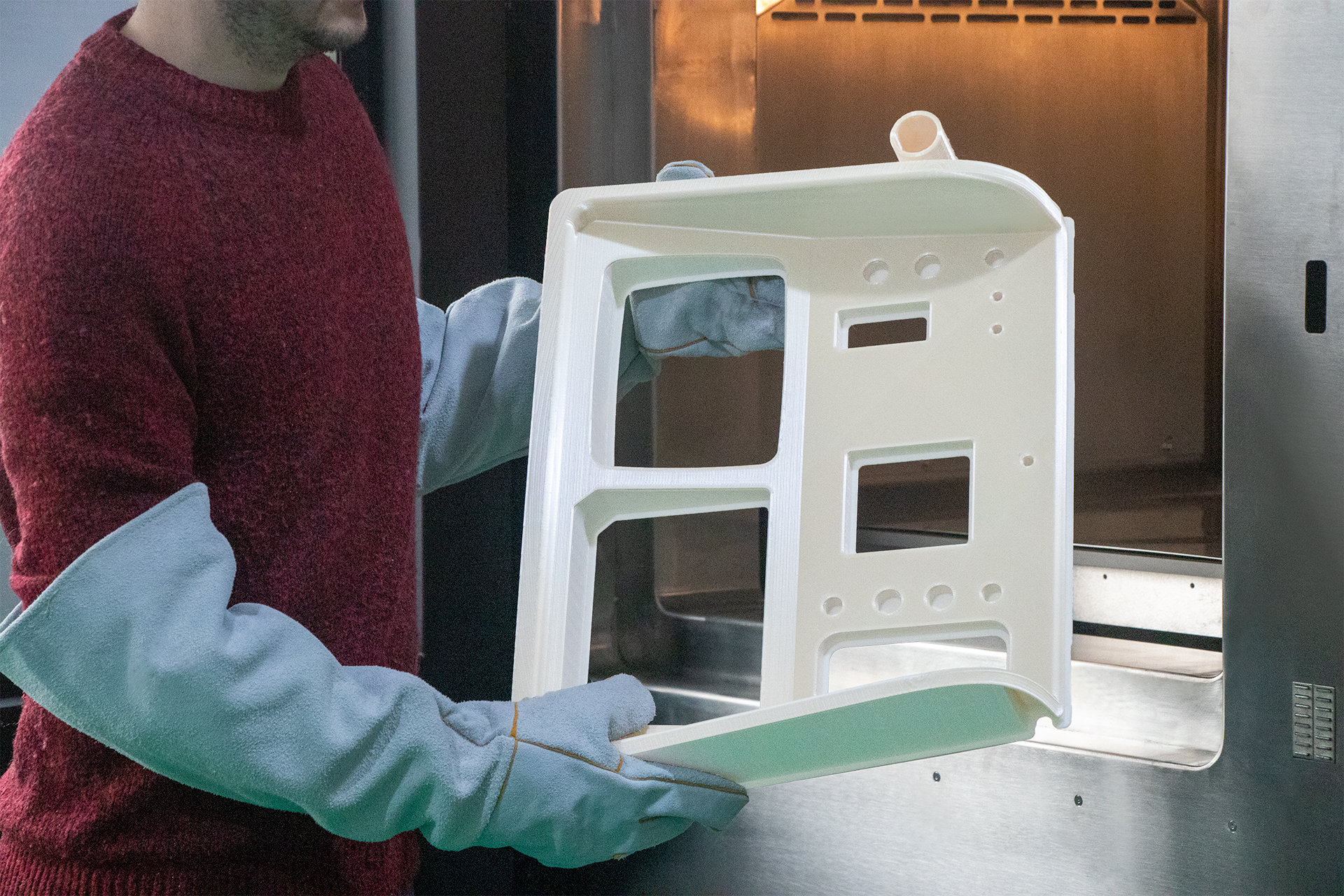

The FUNMAT PRO 610HT is constructed particularly for large-scale end-use practical elements, the machine is designed to course of the highest-performance engineering polymers in the marketplace, together with PEEK, ULTEM(PEI), and PPSU. The producer has now shared particulars of the FUNMAT PRO 610HT’s genesis story, and the way 3D printing within the growth course of paved the best way for shorter lead instances, decrease prices, and a profitable launch.

► Large build volume (610 mm x 508 mm x 508 mm)

► High accuracy 3D Printing Users can achieve 50-micron (0.05mm), high-resolution, industrial-quality 3D printing

► Print speed of up to XY: 500 mm/s Max , Z: 300 mm/s Max

► Dual Extruders with two nozzles going up to 500ºC, you can print virtually any filament on the market

► Designed for high-performance & high-temperature polymers

-

500° Nozzle — 160°C Buildplate — 300ºC Chamber

FEATURES

HIGH-TEMP DUAL EXTRUDER

Using its dual nozzles, the FUNMAT PRO 610HT is ideal for printing large high-performance functional materials using materials like PEEK, ULTEM™(PEI), PPSU & more

BUILD SIZE

The 610 HT provides capabilities and advantages with it’s large build plate of 610 mm x 508 mm x 508 mm. With these dimensions, limitations on size will rarely be anechallenge.

INDUSTRIAL DESIGN

MOTION SYSTEM

Increased print speed with high precision motion systems

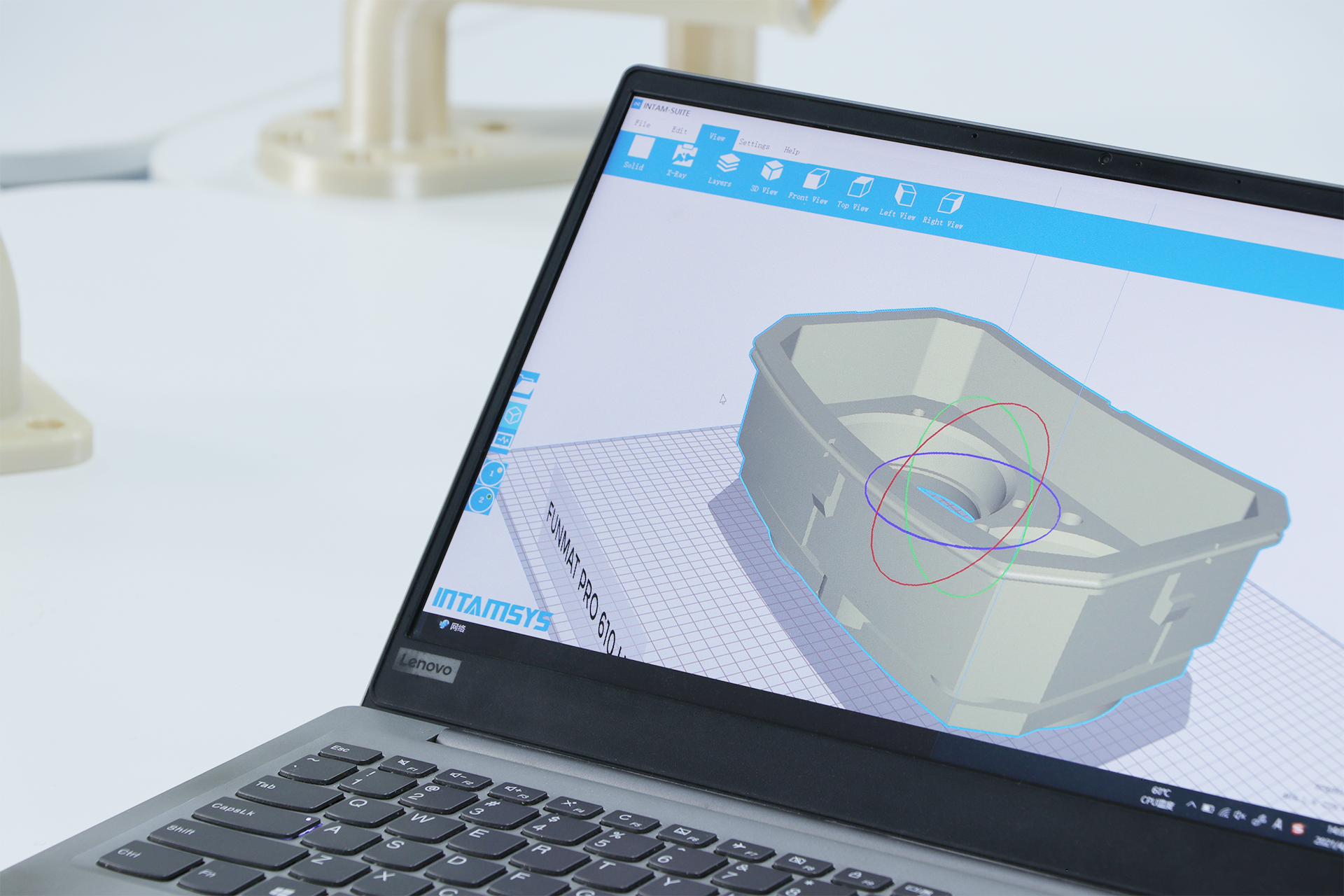

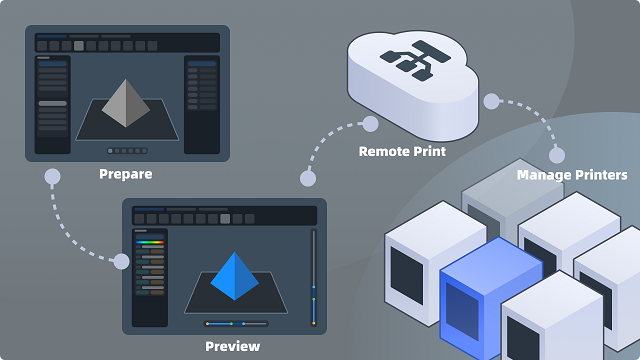

PRECONFIGURED SLICER FROM INTAMSYS

Printer profiles are pre-configured in the INTAMSUITE NEO software for easy operation, straight out of the box.

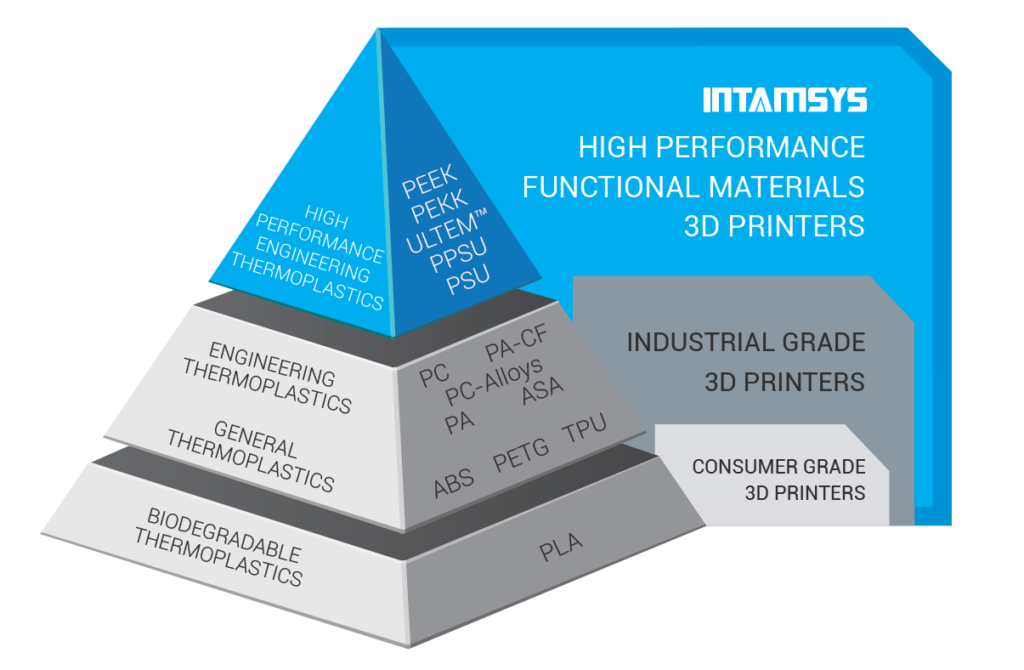

PRINT HIGH-PERFORMANCE MATERIALS: 610HT

ADVANCED FEATURES OF NEXT-GEN 3D PRINTING

Optimize your slicing experience with INTAMSUITE, our in-house developed slicing software tailored exclusively for our machines.

Includes:

3D Printing Slicing Software

Integrated Platform from PROCESS PREPARATION to MONITORING

Take control of your prints with intuitive and powerful slicing capabilities. Print high-quality parts right from your desktop.

Speak With an Expert!

Fill out this our quick contact form or call us today- (888) 696-7226

FUNMAT PRO 610HT

LARGE BUILD VOLUME 3D PRINTING

DUAL NOZZLE 3D PRINTING

DUAL NOZZLE 3D PRINTING

TECHNICAL SPECIFICATIONS

| Build volume | ( 610 mm x 508 mm x 508 mm) | |

| Print speed | XY:500 mm/s Max, Z: 300 mm/s Max | |

| Layer thickness | 0.15 .mm – 0.3 mm | |

| Bed Leveling | Automatic Leveling | |

| Build Platform | Vacuum Absorption Platform | |

| Extruder | Dual Extruders | |

| Nozzle Temperature | Max. 500°C | |

| Platform Temperature | Max. 160°C | |

| Chamber Temperature | Max. 300°C | |

| Printing technology | FFF- Fused-Filament-Fabrication | |

| Certified materials | PEEK/PEEK-CF/PEEK-GF/PEKK/ULTEMTM (PEI)/PPSU/PC-HT/PC/PC Alloys/ PA-HT/PA/PA-CF/ASA/ABS/HIPS/Carbon Fiber-Filled/GlassFiber-Filled/ ESD-Safe and others |

|

| Printer weight | Approx. 3,197 lbs | |

| Size | 67.3 x 54.7 x 80.1 in (WxDxH) | |

| Power | 1500W, 220V 30A | |

| Safety Certifications | FCC and CE | |

| Smart Design | Onboard with multi-touch panel + Camera | |

| File transfer | USB , Wifi, Ethernet | |