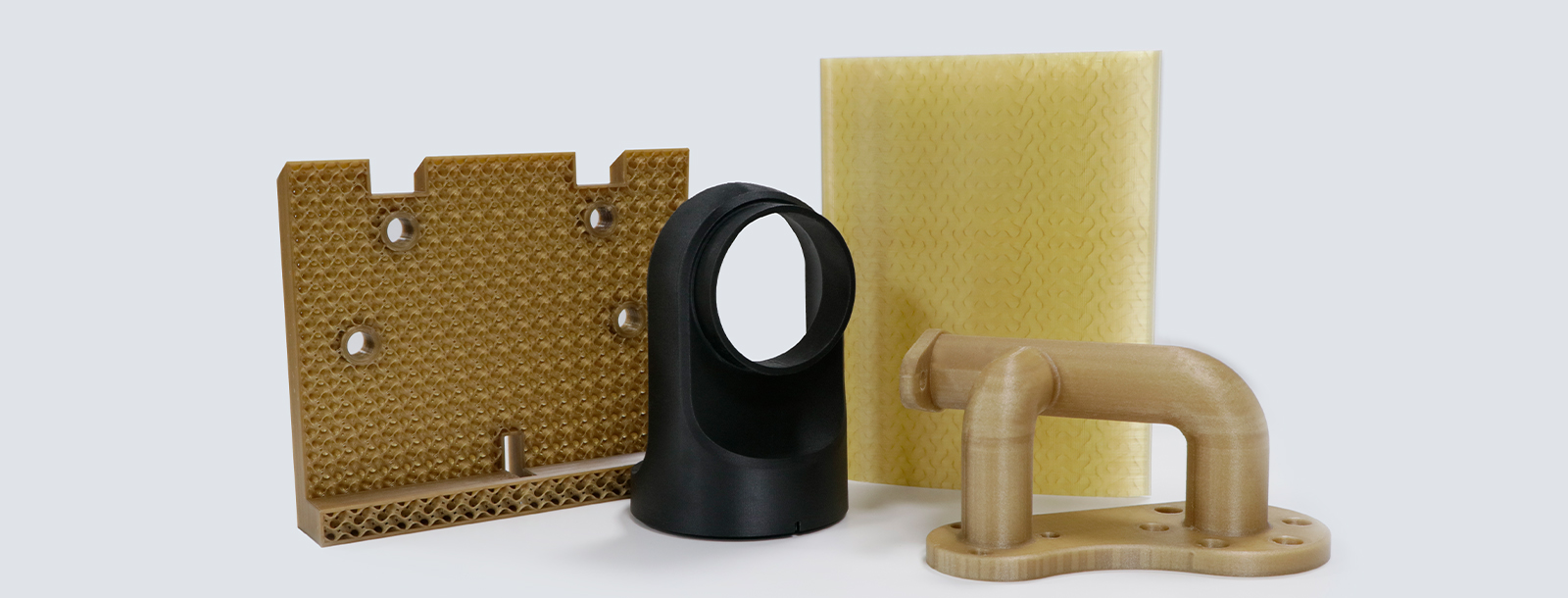

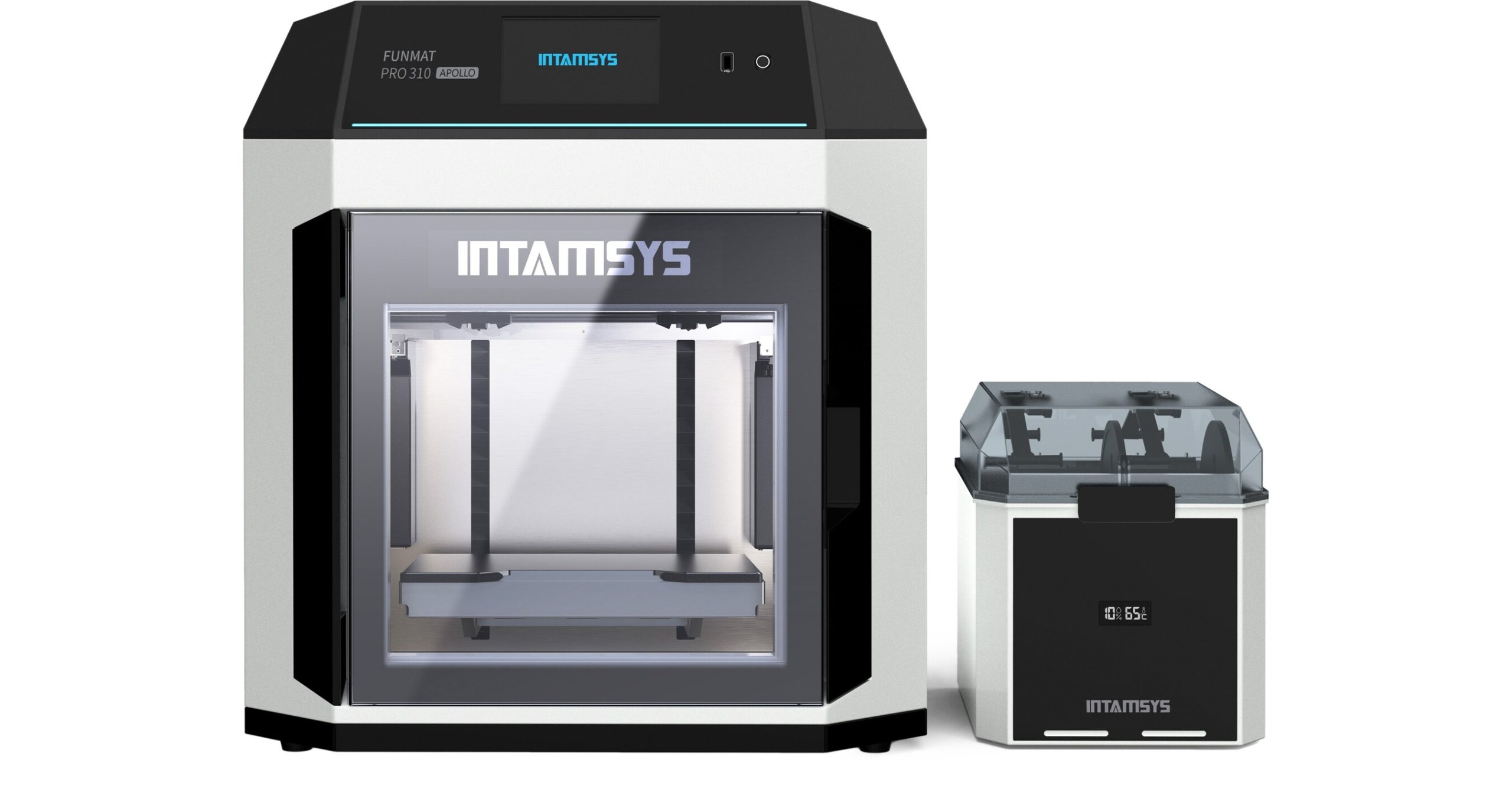

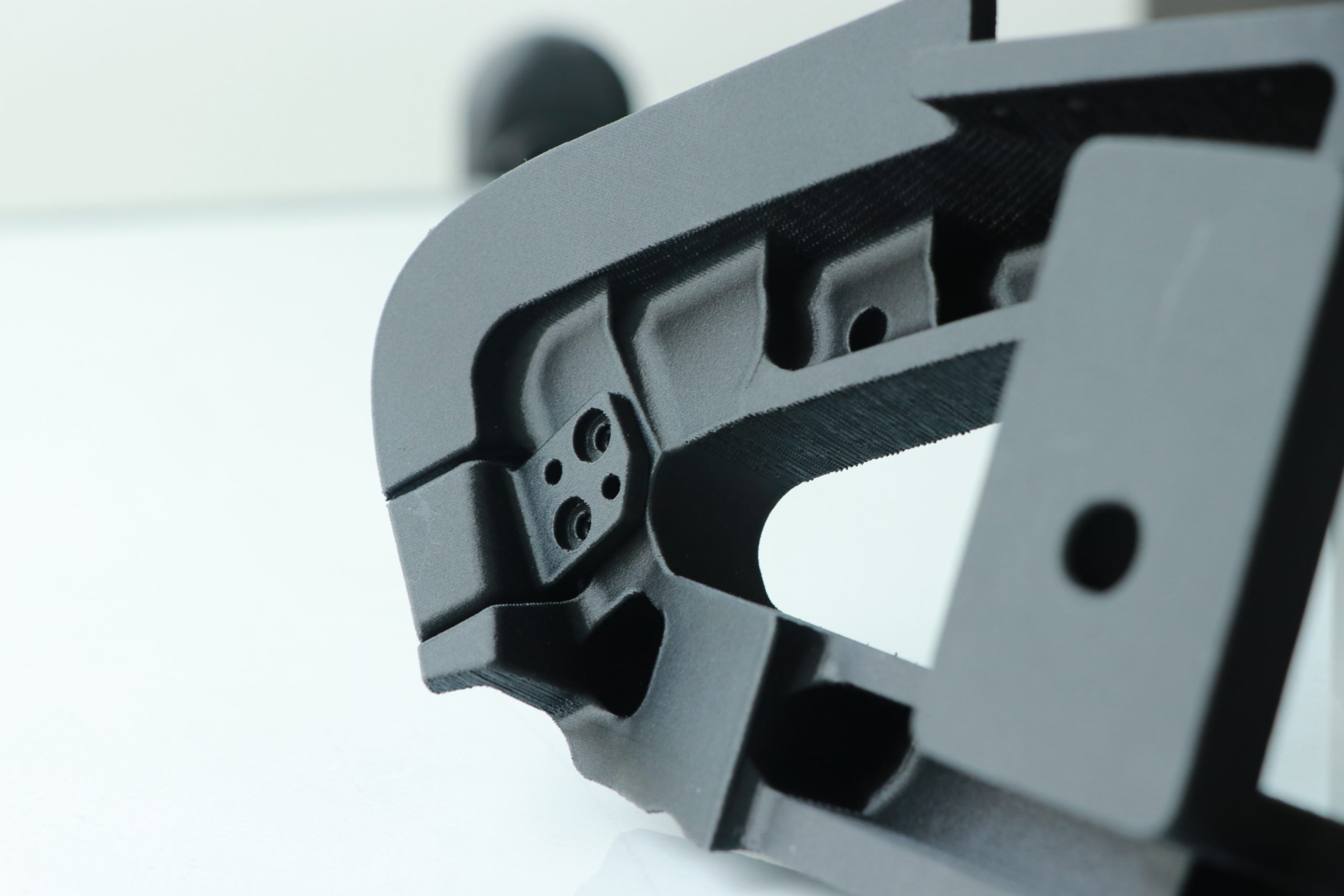

The FUNMAT PRO 310 APOLLO represents a new generation of industrial-grade, high-temperature 3D printing. Purpose-built for the PAEK family of polymers, this platform enables manufacturers to move beyond prototyping and into true end-use production, delivering parts that rival machined metal in thermal stability, chemical resistance, and mechanical performance.

► Large build volume Single Nozzle: 305 × 260 × 260 mm

Dual Nozzles: 260 × 260 × 260 mm

► High accuracy 3D Printing Users can achieve 50-micron (0.05mm), high-resolution, industrial-quality 3D printing

► Print speed Print up to 200 mm/s with the first PAEK-optimized dual-nozzle system in the industry; more than 4× faster than standard PEEK printers.

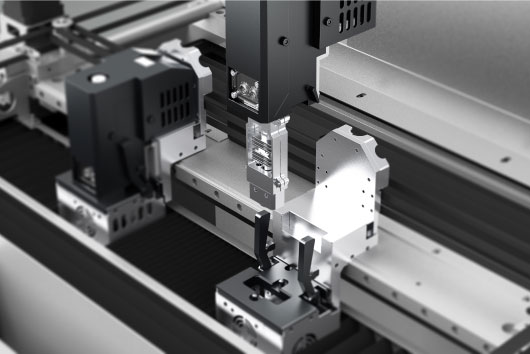

► IDEX Dual Extruders Independent dual-extrusion system optimized for high-temperature materials; enables mirror mode and duplicate mode for doubled productivity.

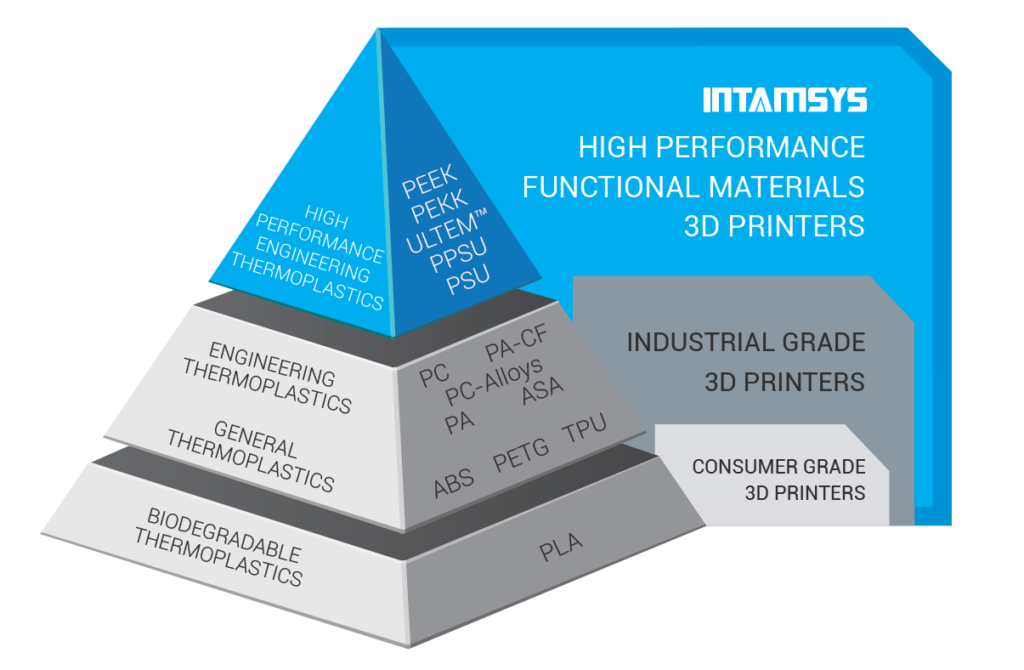

► High Performance Materials Printing

-

Supports full-range PAEK materials (PEEK, PEKK, PEEK-CF, PEEK-GF).

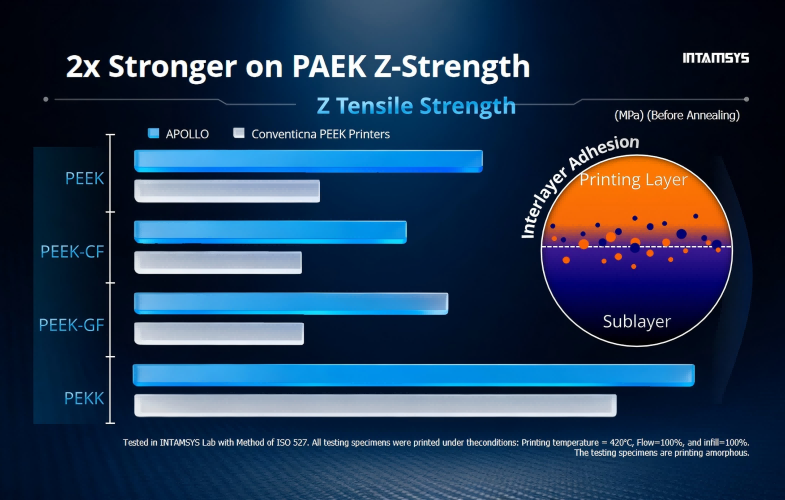

Engineered for the Toughest Jobs – 2× stronger: up to 40 MPa Z-tensile strength.

Built for Continuous Production

-

Print without pause: Dual 3 kg active dry boxes (up to 65 °C) to ensure up to one week of uninterrupted printing with no material changeovers and no downtime.

-

Traceability built-in: Real-time data logging with INTAMQuality™ system, RFID-based spool recognition for full part tracking and material traceability.

-

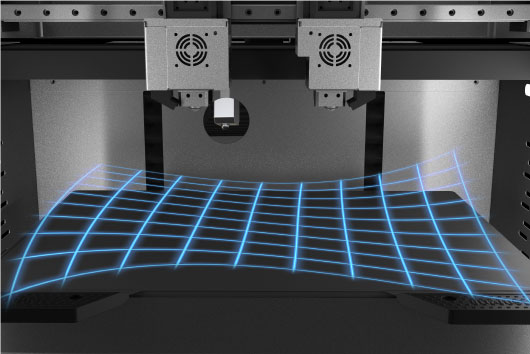

Designed for high-temperature stability: Optimised hardware/software for PAEK materials, stable chamber temperature up to ~100 °C to minimise warping and improve repeatability.

No Trade-Offs Between Speed and Strength

- Designed to shorten production cycles while meeting the demands of batch manufacturing and end-use delivery

Intelligent Control Platform – Smart, stable, and trackable.

-

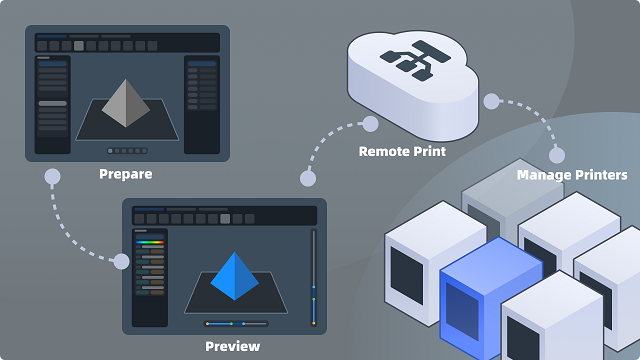

Intelligent planning and adaptation: Powered by INTAMSUITE NEO delivering optimised toolpaths and adaptive process control for every material and geometry.

-

End-to-end monitoring and remote control

Why Manufacturers Choose the APOLLO

PRODUCTION READY PAEK 3D PRINTING

PAEK-grade materials

PEEK, PEKK, and reinforced PAEK blends—are notoriously difficult to process. The APOLLO’s controlled thermal architecture and precision extrusion system allow you to reliably manufacture strong, dimensionally stable components without warping or deformation.

FOR CONTINUOUS OUTPUT

Whether you’re running short-run batches or around-the-clock production, the APOLLO is optimized for consistent, repeatable output. Its independent dual-extrusion configuration enables higher productivity workflows while maintaining material purity and part accuracy.

ENGINEERED STABILITY AT ELEVATED TEMPERATURES

USER-FRIENDLY INTERFACE

PAEK materials demand steady chamber conditions to maintain mechanical integrity. The printer’s advanced thermal design maintains a tightly regulated internal environment, ensuring: Strong Z-layer bonding – Minimal shrinkage – High repeatability – Superior surface quality

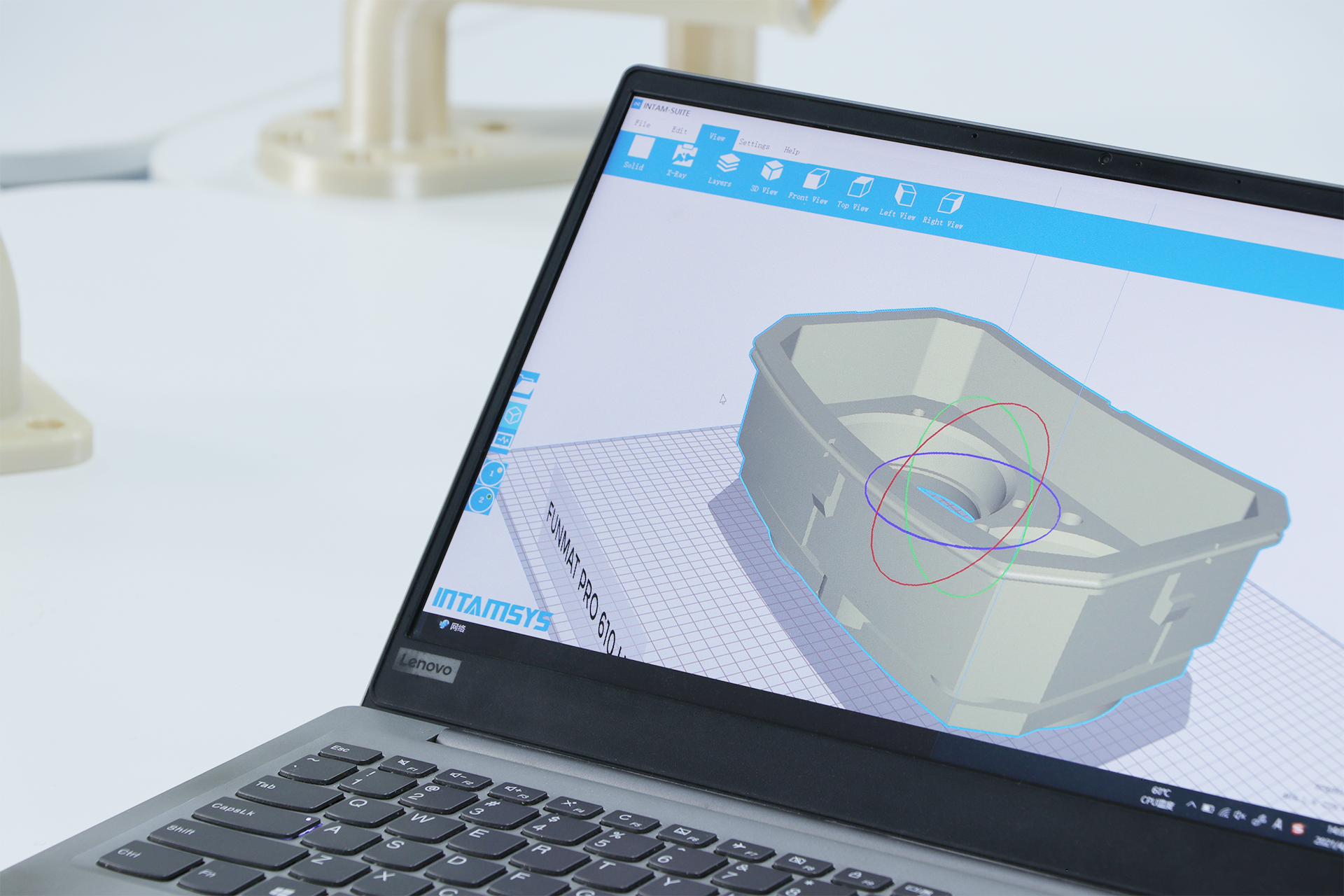

PRECONFIGURED SLICER FROM INTAMSYS

Printer profiles are pre-configured in the INTAMSUITE NEO software for easy operation, straight out of the box.

Ultra-fast printing · Full-strength functional parts · True continuous production

Includes:

3D Printing Slicing Software

Integrated Platform from PROCESS PREPARATION to MONITORING

Speak With an Expert!

Fill out this our quick contact form or call us today- (888) 696-7226

FUNMAT PRO 310

BRING INDUSTRIAL 3D PRINTING TO YOUR DESKTOP

TECHNICAL SPECIFICATIONS

| Category | Specification |

|---|---|

| Build Volume | Single Extruder: 305 × 260 × 260 mm Dual Extruders: 260 × 260 × 260 mm |

| Extrusion System | Independent Dual Extrusion (IDEX), high-temperature capable |

| Nozzle Temperature | Up to 500°C (supports PAEK/PEEK/PEKK-grade materials) |

| Bed Temperature | Up to 160°C (high adhesion for semi-crystalline polymers) |

| Chamber Temperature | Actively heated, stable high-temperature environment for PAEK-class performance |

| Print Speeds | Up to 200 mm/s (optimized for high-temp engineering materials) |

| Supported Materials | Full PAEK family: PEEK, PEKK, PAEK-CF, PAEK-GF + engineering polymers (ABS+, ASA, PC, PA12-CF, PPS, PPS-GF, TPU, support materials) |