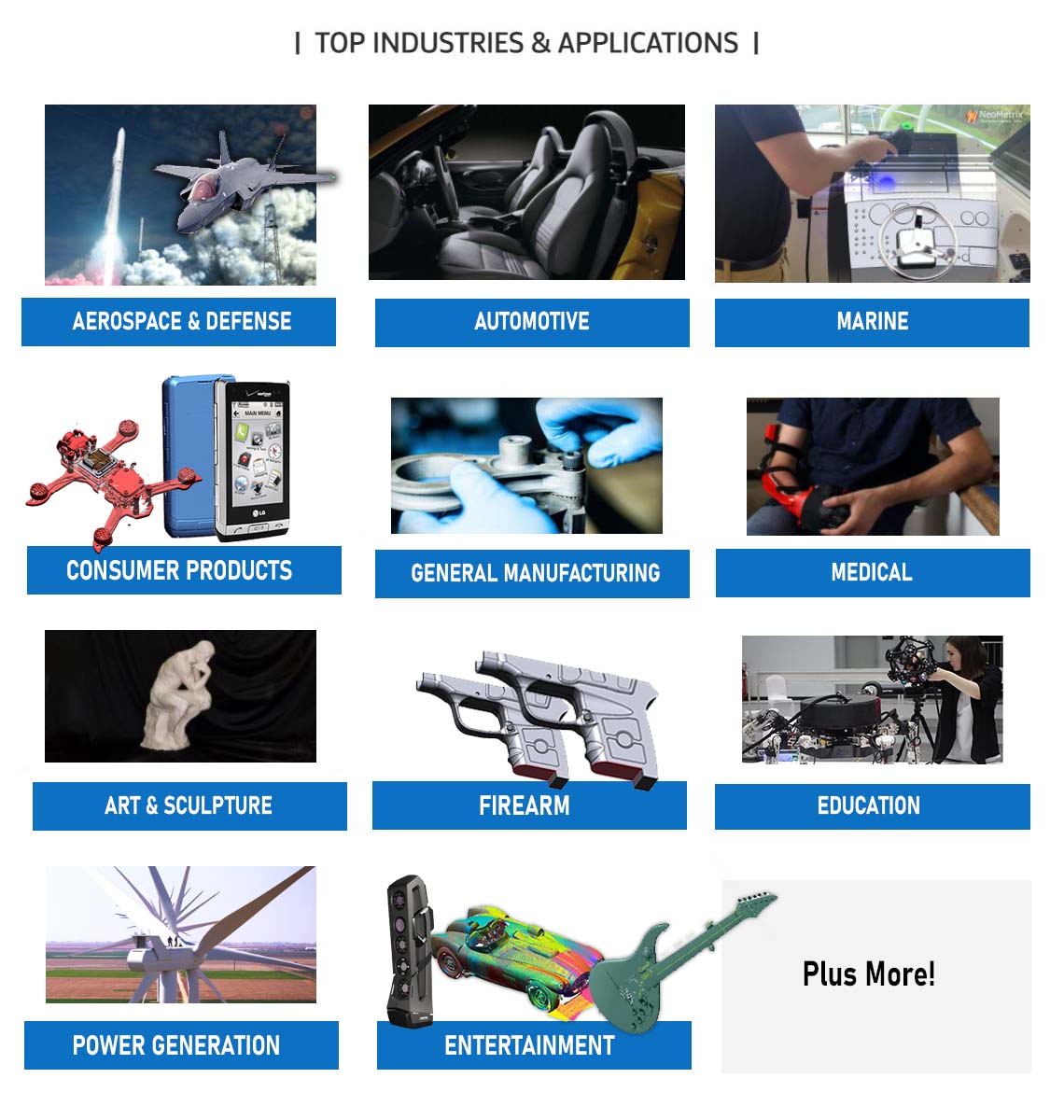

Industrial High-Speed 3D Printing – Maximize Productivity

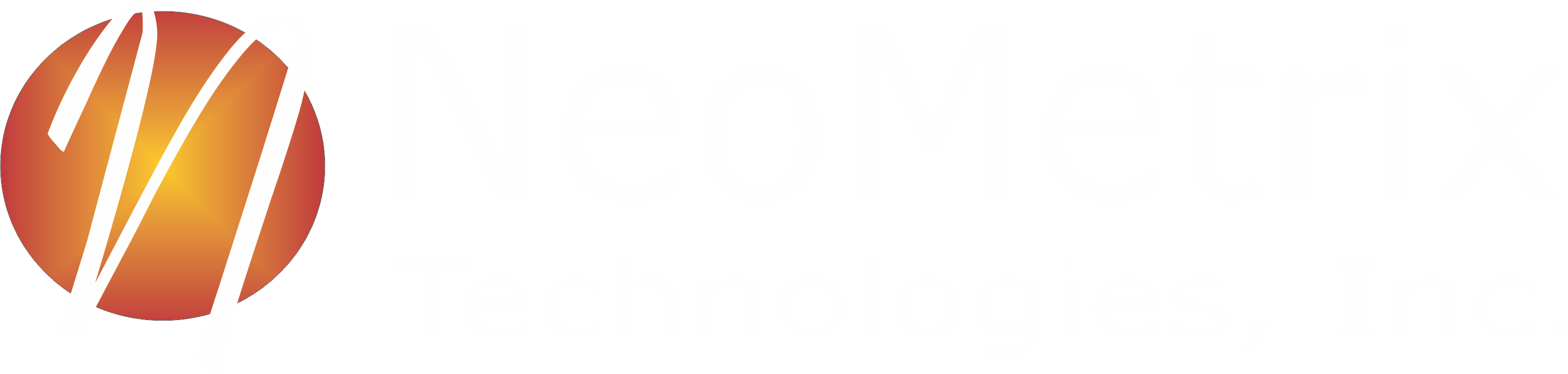

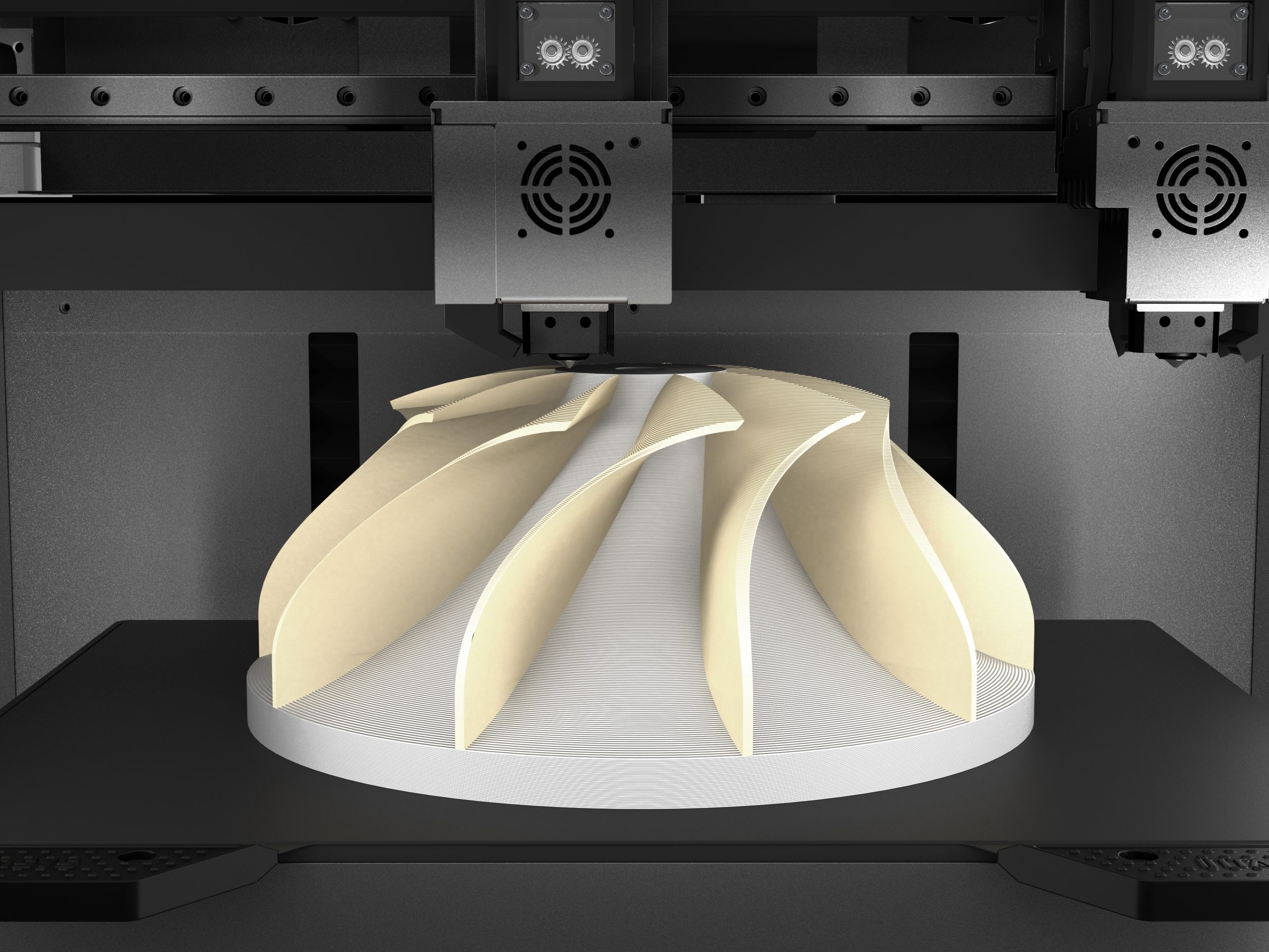

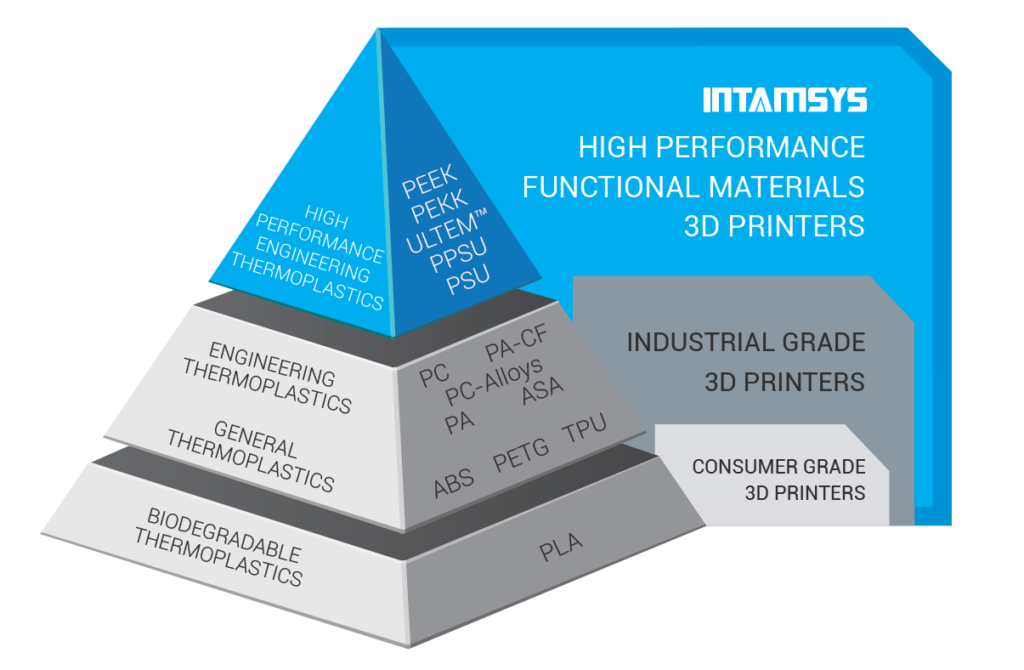

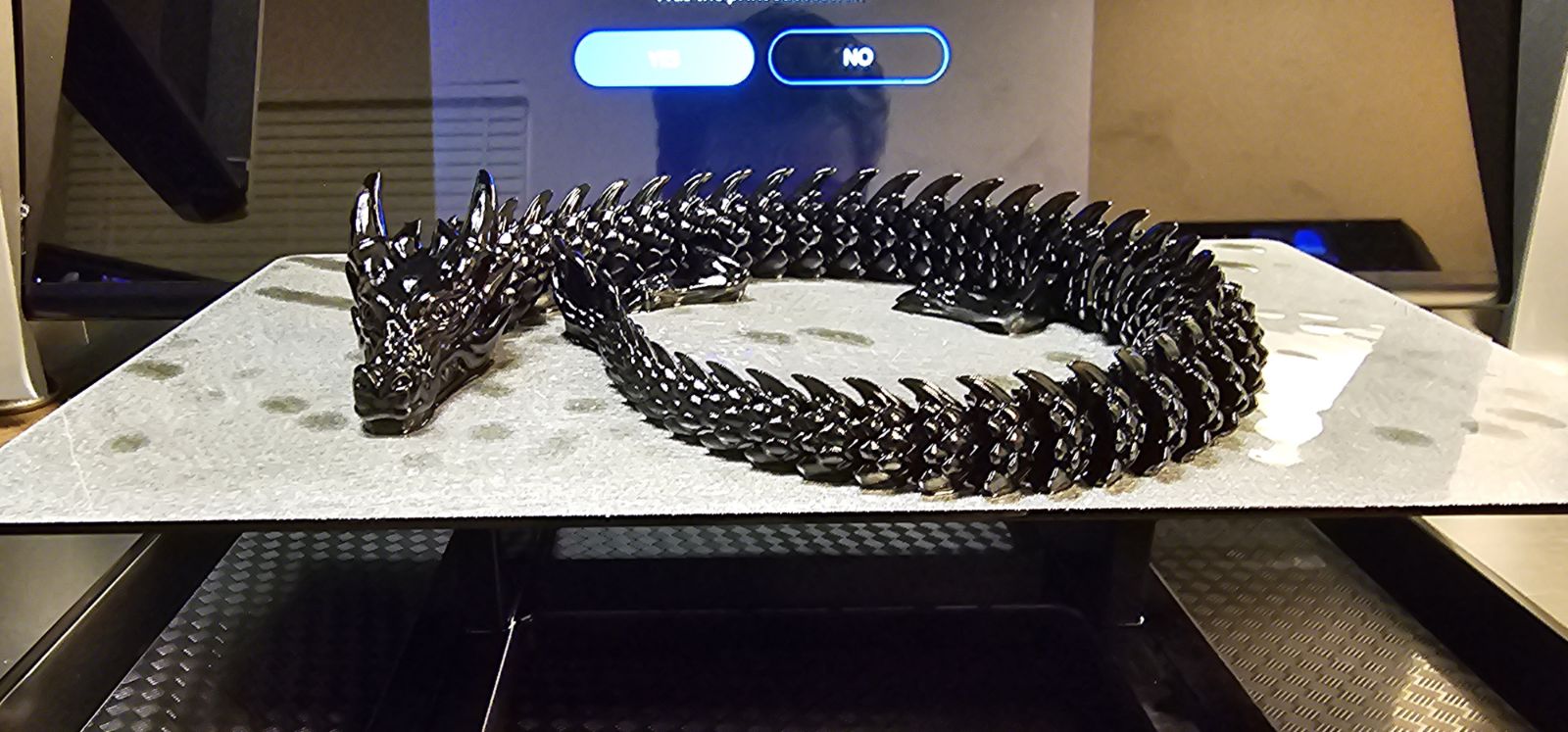

The INTAMSYS FUNMAT PRO 310 NEO is a versatile and robust industrial-grade 3D printer. With a large build volume, dual extruder system, and advanced material compatibility, it delivers high-quality prints for various applications. NOW PRINTS TPU!

► Large build volume Single Nozzle(305 mm x 260 mm x 260 mm), Dual Nozzle (260 mm x 260 mm x 260 mm),

► High accuracy 3D Printing Users can achieve 50-micron (0.05mm), high-resolution, industrial-quality 3D printing

► Print speed of up to 500 mm/s max. Offers 8 high-speed material processing options, achieving a high productivity range and engineering-grade quality

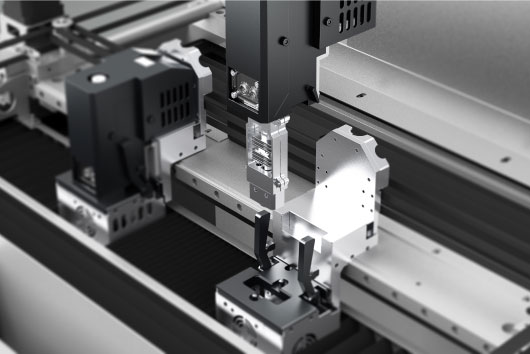

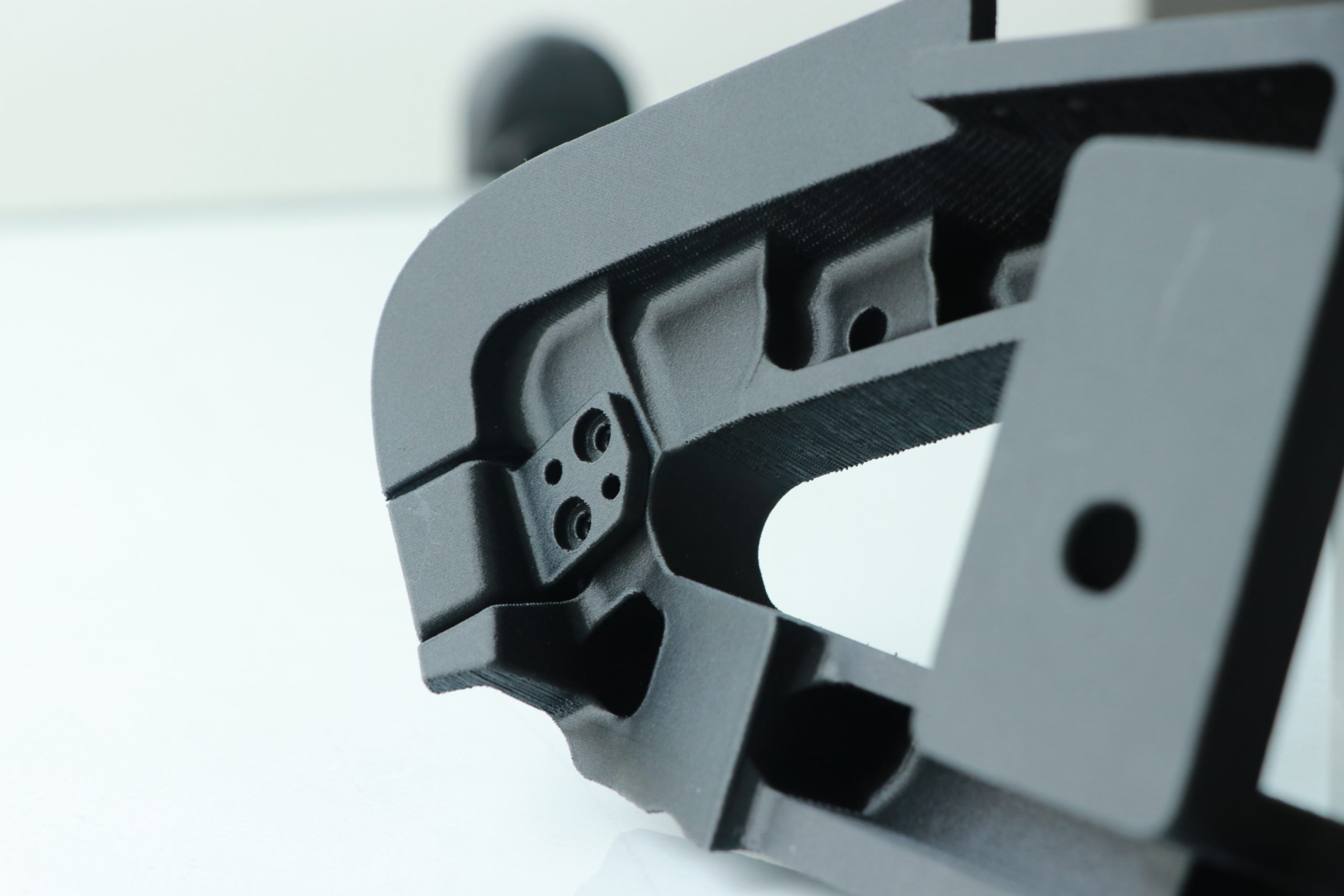

► IDEX Dual Extruders Two printheads can run independently of each other along the same axis during the printing process, which ensures the printing quality of complex geometries parts in conjunction with the engineering material support solution.

► Designed for high-performance & high-temperature polymers

-

300°C Nozzle — 160°C Buildplate — 100ºC Chamber

Super High-Speed Printing

- Offers 8 high-speed material processing options, achieving a productivity range of 500-1000g/day

- Doubles capacity for duplicate and mirror mode, reaching 1kg/day.

- Maintains perfect control over print quality and precision at high speeds, delivering reliable continuous production to meet industrial application demands.

Next-Generation Print Mainboard, Driving High-Speed Printing Innovation

- Powered by NXP’s advanced MCU, this mainboard provides the robust computing power needed for high-speed printing..

Perfect Surface Finish with Advanced Motion Control Algorithms

- Intelligent Speed Prediction: Predicts printing speeds based on path complexity to maintain exceptional surface quality

- Flow Compensation Technology: Dynamically adjusts the material extrusion rate to prevent surface defects during high-speed printing.

FEATURES

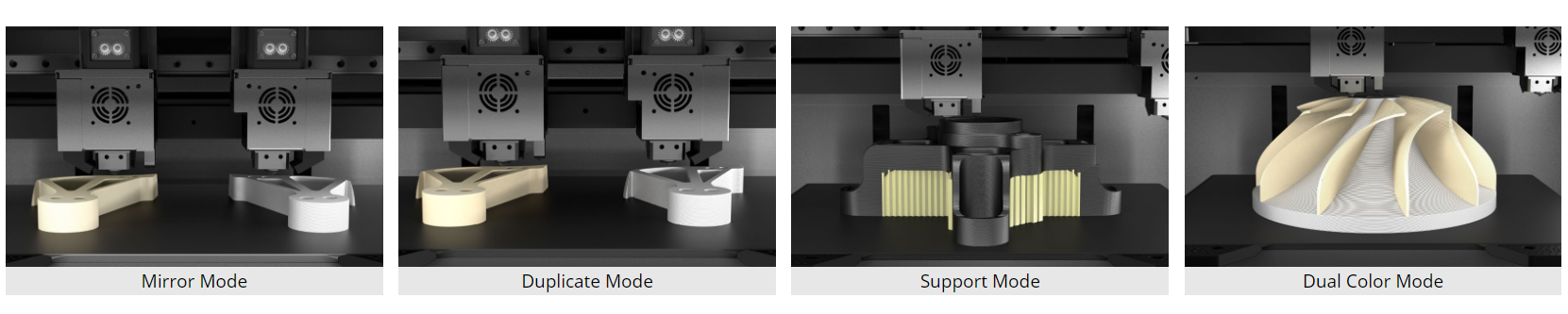

INDEPENDENT DUAL EXTRUDERS

Two printheads can run independently of each other along the same axis during the printing process, which ensures the printing quality of complex geometries parts in conjunction with the engineering material support solution.

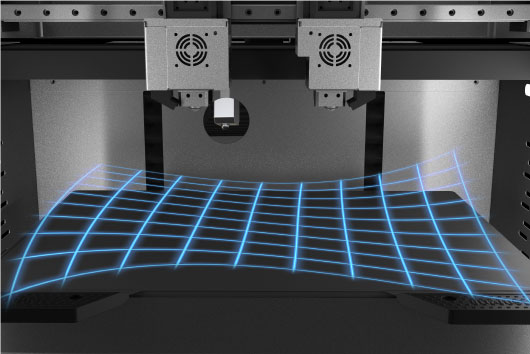

ENHANCED PRINTING PLATFORM

Auto mesh leveling with 100 points surface flatness measurement and automatic Z-axis compensation. Flexible build plate for easy part removal Glue-free bed adhesion.

USER-FRIENDLY INTERFACE

Intelligent interactive design, user-friendly interface, with task queue management function. Camera, Filament Drybox, + MORE

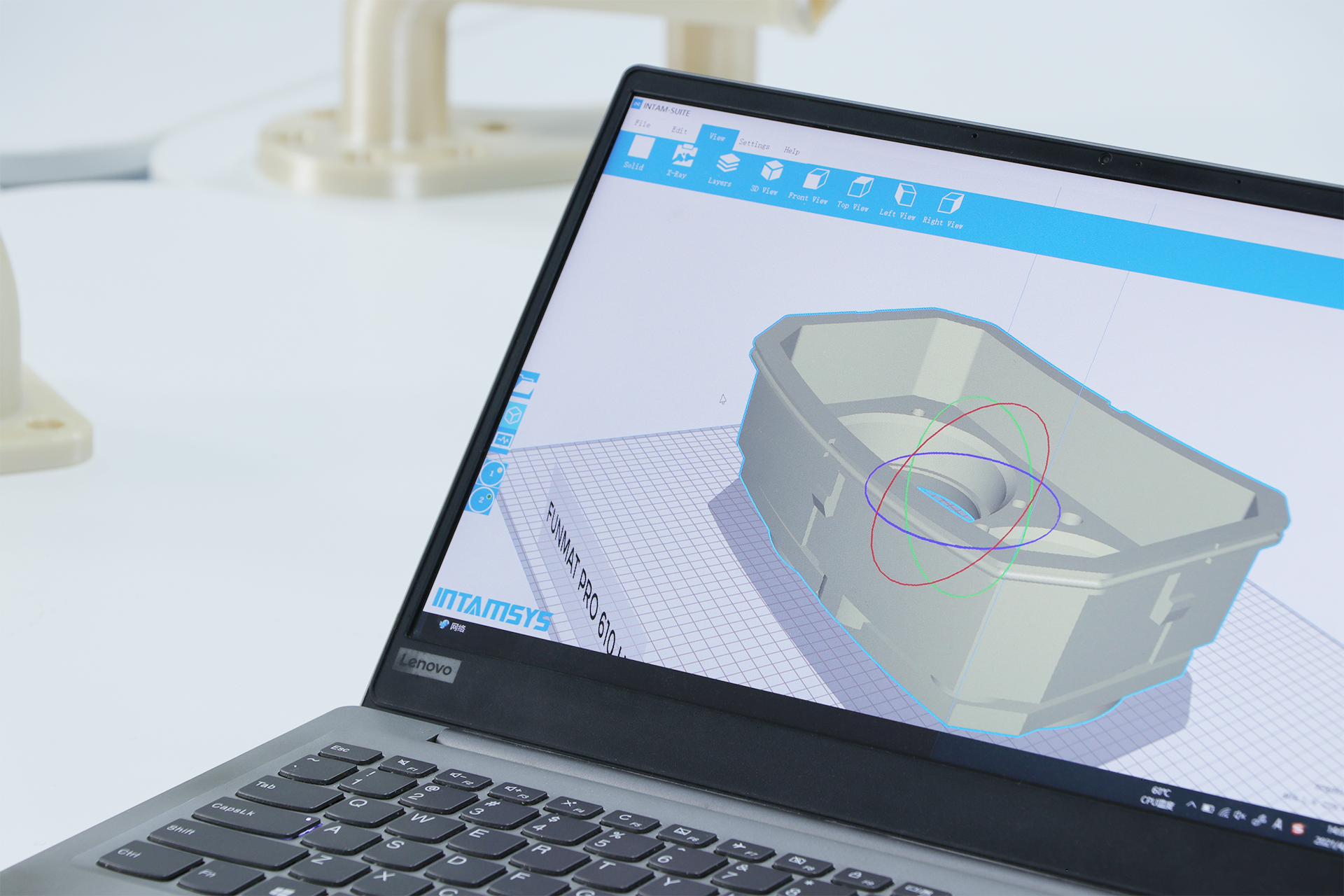

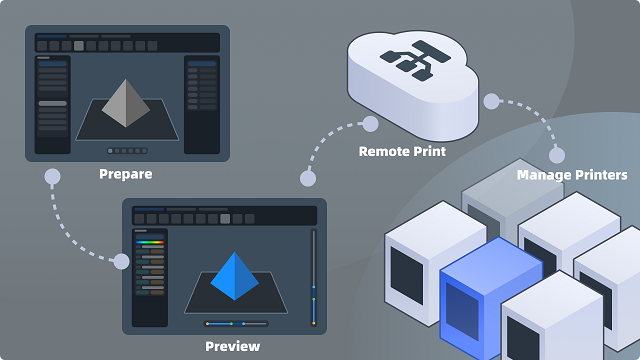

PRECONFIGURED SLICER FROM INTAMSYS

Printer profiles are pre-configured in the INTAMSUITE NEO software for easy operation, straight out of the box.

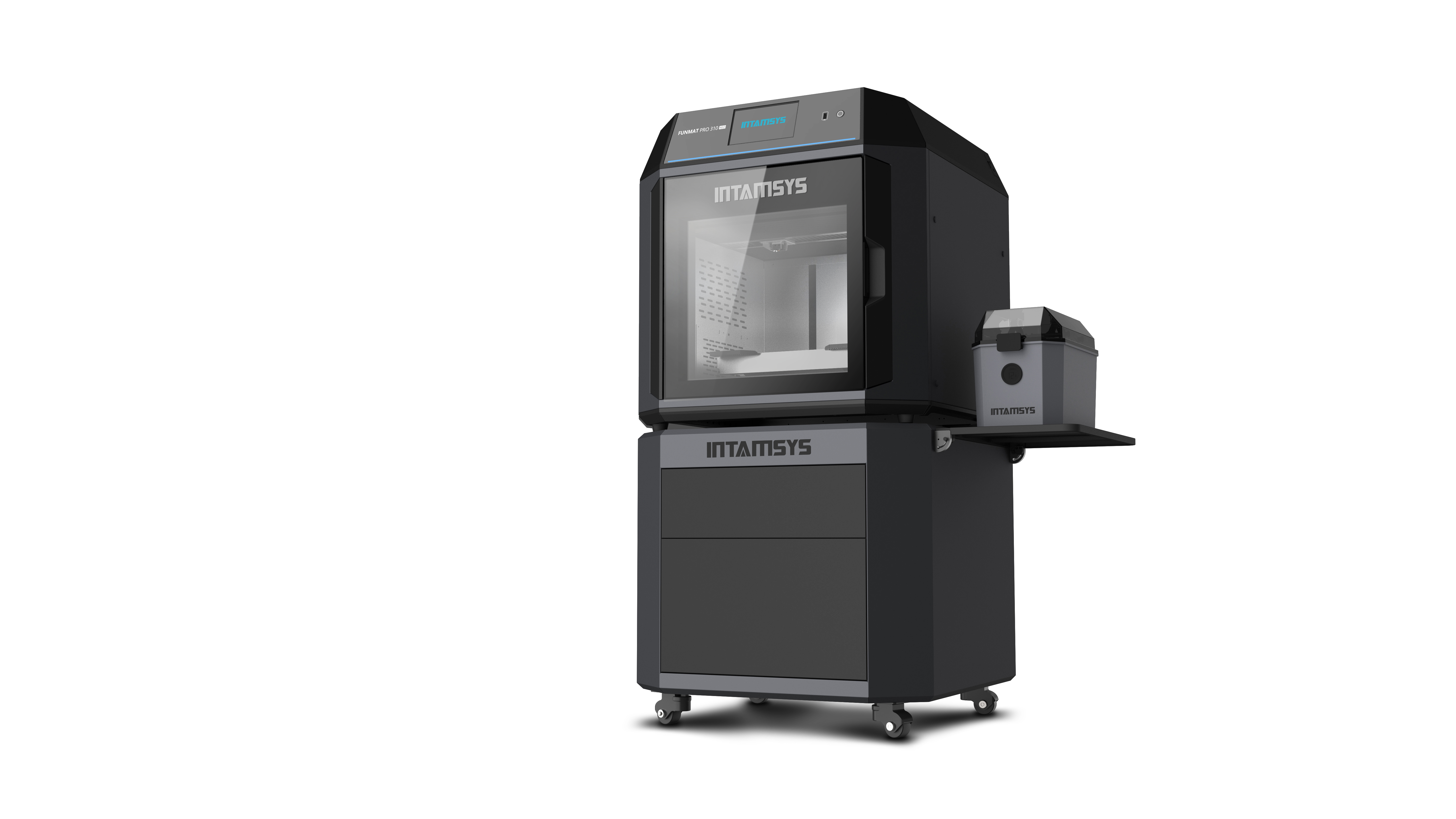

INDUSTRIAL HIGH-SPEED PRINTING UNLEASHES CAPACITY LIMITS

Multiple Printing Modes for Multiple Printing Needs

Mirror/Copy mode for improved batch printing efficiency

Support mode printing enables high-quality finish complex geometries printing accuracy of printed parts

Dual-color printing brings more design inspiration

Includes:

3D Printing Slicing Software

Integrated Platform from PROCESS PREPARATION to MONITORING

Speak With an Expert!

Fill out this our quick contact form or call us today- (888) 696-7226

FUNMAT PRO 310

BRING INDUSTRIAL 3D PRINTING TO YOUR DESKTOP

TECHNICAL SPECIFICATIONS

| Build volume | ( 305 mm x 260 mm x 260 mm) | |

| Print speed | 120 mm/s max. | |

| Layer thickness | 0.1-0.3mm | |

| Bed Leveling | Automatic Leveling | |

| Build Platform | Magnetic Flexible Build Plate | |

| Extruder | IDEX Dual Extruders | |

| Nozzle Diameter | Default:0.4 mm (Optional 0.25/0.6 mm) | |

| Nozzle Temperature | Max. 300°C | |

| Platform Temperature | Max. 160°C | |

| Chamber Temperature | Max. 100°C (Enclosed) | |

| Printing technology | FFF- Fused-Filament-Fabrication (FFM) | |

| Certified materials | PC, PC-ABS, PA6/66, PA66-CF, PA12-CF, ABS, ABS+, SP3030, ASA, PLA, HIPS, PVA, ESD-safe | |

| Printer weight | Approx. 441lbs | |

| Size | 27.6 x 25.8 x 27.6 in (WxDxH) | |

| Power | 200~240V/15A , Max Power 1600W | |

| Safety Certifications | CF, FCC, SGS | |

| GUI | Onboard with multi touch panel + Camera | |

| File transfer | USB , Wifi, Ethernet | |