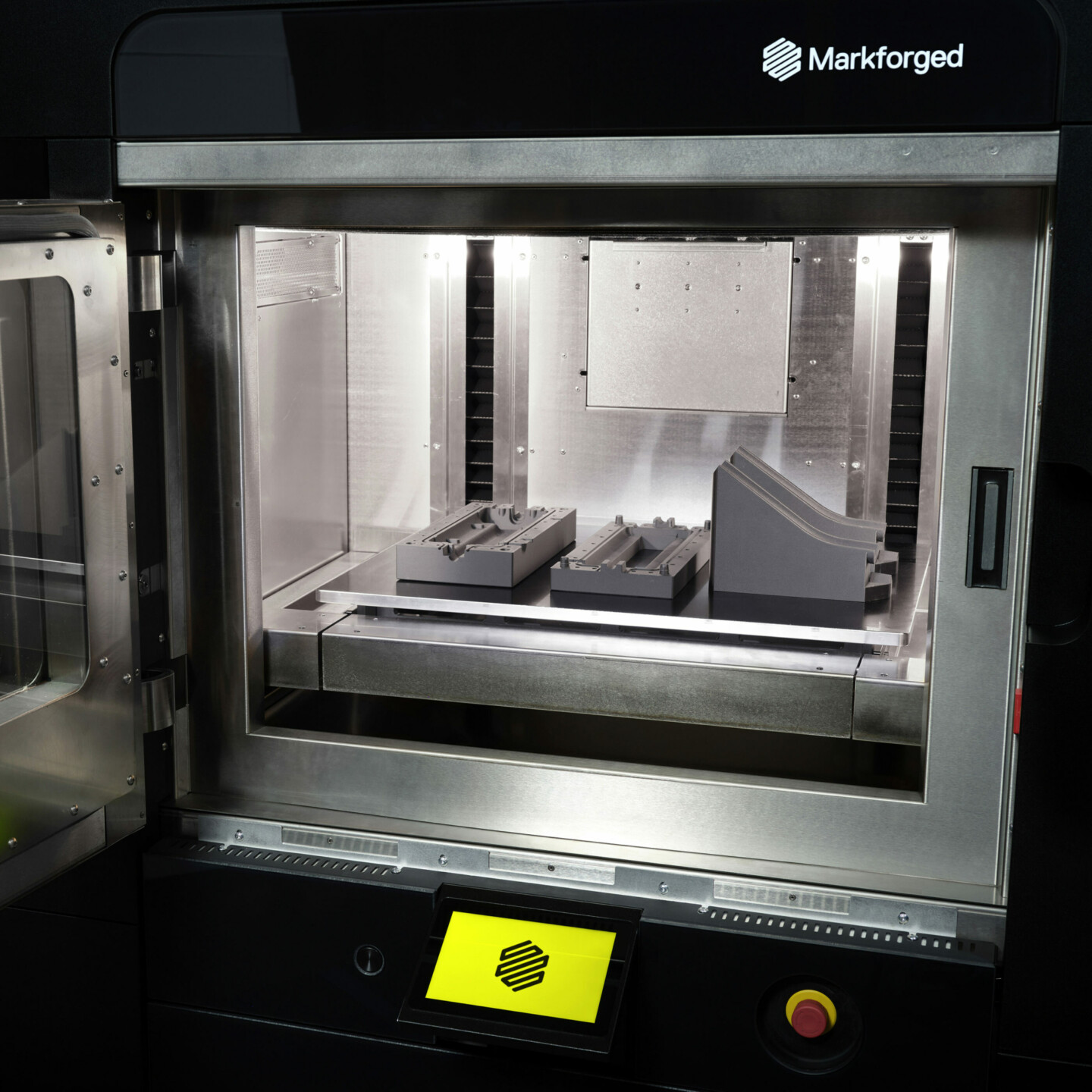

SOLVE BIGGER, AND MORE COMPLEX CHALLENGES

Engineered from the ground up for unparalleled performance and consistency, FX20 brings our patented composite technology to a larger scale and scope of applications and industries. Capable of printing high-temperature thermoplastics with continuous carbon fiber, this beast of a machine delivers high-strength, aerospace-grade parts at the click of a button.

Enter your info to receive updates about the FX20 3D Printer!

Massive Builds, Faster

The FX20 pairs size and throughput to make larger builds at incredible speeds,

delivering the transformational benefits of The Digital Forge at a new scale.

Functional Parts from Factory to Flight

Built for everything from performance tooling and fixtures to flight-ready production parts —

the FX20 can reinforce ULTEM™ 9085 with continuous carbon fiber.

Production-Ready Performance

A precision-designed, sensor-driven machine delivers

breakthrough reliability and performance with a simple user experience.

The FX20 is the largest and most precise machine Markforged has ever produced.

It features an 80L heated build chamber and massive precision ground vacuum bed with reusable print sheets. The motion control system offers closed loop control through precision linear encoders, and is tuned to move the 3kg print head rapidly and accurately. FX20’s turbo mode builds parts faster than any Markforged machine, while new XL spools offer four times the material without spool changeover.

The FX20 is remarkably easy to use. It features a 7 inch touchscreen from which users can control every aspect of the printer. Automated calibration and levelling reduces operator input, while a wide variety of sensors give live feedback on machine performance. A material bay contains two active XL spools and can store two more with precise moisture control.

- Printing Process

- Fused Filament Fabrication, Continuous Fiber Reinforcement

- Z Layer Resolution

- 50 μm – 250 μm

- Printing Media

- Polymer Filament, Continuous Fibers

- Internal Part Geometry

- Closed Cell Infill with Continuous Fiber Reinforcement

- Print Bed

- Precision Machined Aluminum

High-Performance Materials

Onyx™

Onyx FR™

Onyx ESD™

ULTEM™ 9085

Nylon

Carbon Fiber

Carbon Fiber FR

Aramid Fiber (Kevlar®)

HSHT Fiberglass

Fiberglass

Markforged’s Eiger Software

With automatic version control, real-time fleet management and cloud-based collaboration, Eiger is the world’s most advanced 3D printing software. Designed from the ground up to make manufacturing simpler, Eiger enables you to print plastic, metal and composite parts straight from your browser.