Metal X- Metal 3D printing solution for functional metal parts, next-day

The Metal X System is an accessible way to fabricate complex metal parts in a wide variety of advanced metals.

► Build Volume (300 mm x 220 mm x 180 mm)

► Print speed of up to —mm/s

► Layer Resolution of 85 μm – 170 μm (Post-Sinter)

► Printing Process Metal FFF & Bound Powder Filament

► Access to High-Strength Materials – 17-4PH Stainless Steel, Copper, H13 Tool Steel, Inconel 625, A2 and D2 Tool Steel

FEATURES

SPECIALIZED PRINTING TECHNOLOGY

SIMPLE, YET POWERFUL

The Metal X is one of the most intuitive metal 3D printers available today. Print a wide range of materials from stainless steels to copper with minimal training on a closed workflow. Scaling up capacity is easy; just add printers.

SAFE WORKFLOW- TRUSTED TECHNOLOGY

SAFE AND AFFORDABLE

The Metal X is designed to be safe to use and accessible for all fabricators. It costs several times less than DMLS metal 3D printing systems and requires no dedicated operator, no powder management system, and minimal PPE.

MANUFACTURING AT YOUR FINGER TIPS

QUALITY PARTS, FAST

The Metal X is purpose-built for consistent part quality and a seamless user experience. Markforged combines superb software, materials research, and an advanced motion system to deliver industrial-grade parts quickly and reliably.

PROTOTYPING & END-USE PARTS

COMPLETE METAL SOLUTION

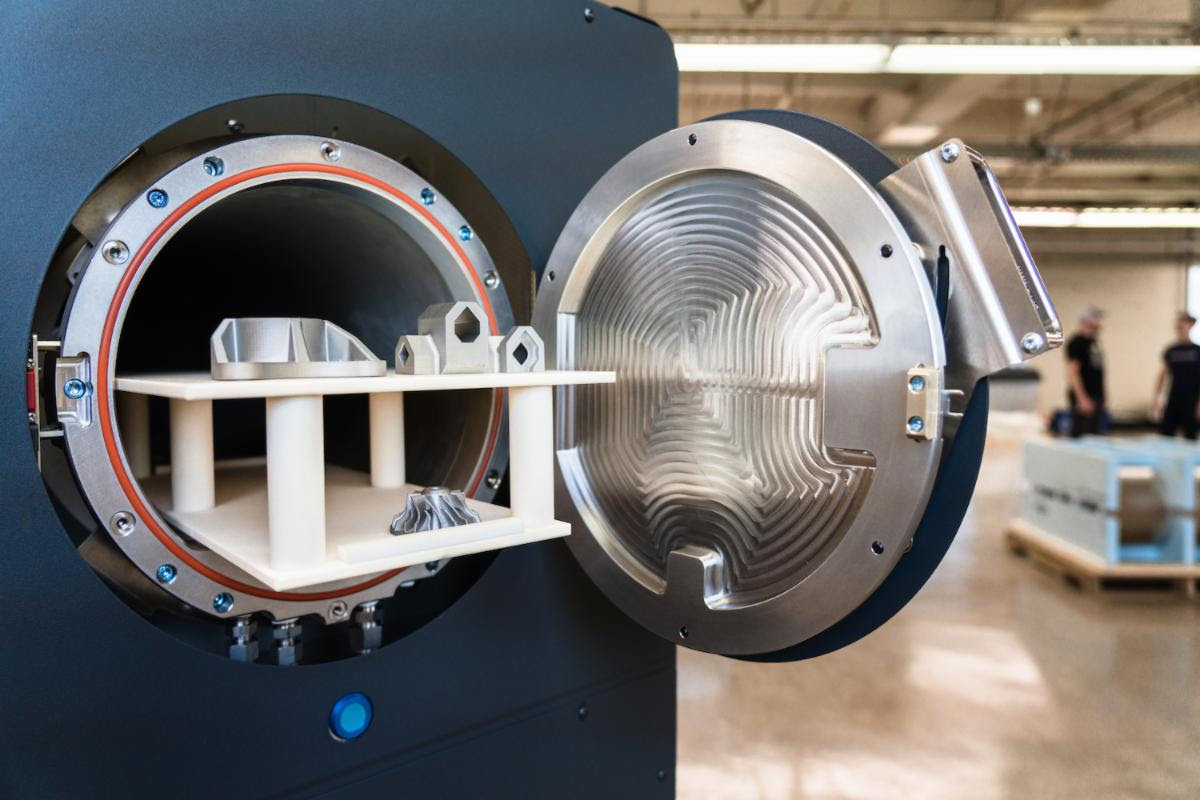

The Metal X comprises a 3-part system: 3D Printer, Sinter Oven, and Wash. It also includes the world’s most advanced 3D printing software- Eiger. Designed from the ground up to make manufacturing simpler.

3D Print Lighter, Stronger, and Faster

3D Printing Aerospace Tools

Simple and safe workflow

designed for any business.

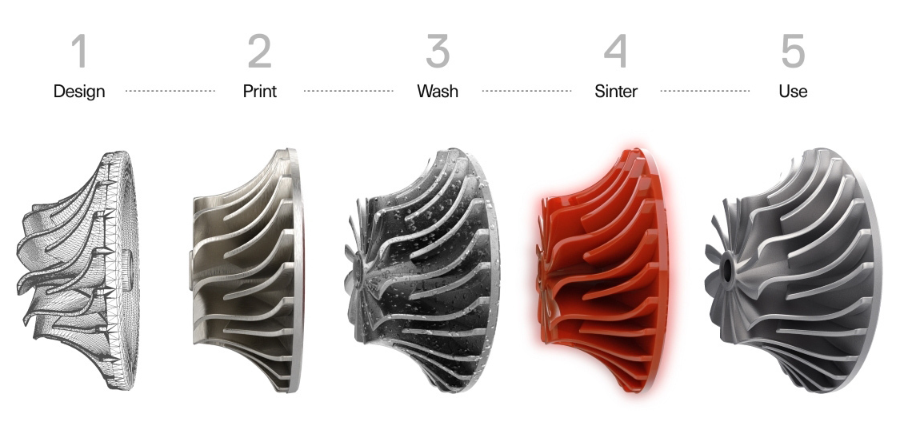

The Metal X makes metal 3D printing simpler than ever before. Go from design to functional 3D printed metal parts quickly, easily, and with a more affordable cost.

The Markforged Metal X additive manufacturing process combines metal injection molding (MIM) and fused filament fabrication (FFF) technologies together into Bound Powder Extrusion. BPE provides a simple, cost-effective way to create metal parts.

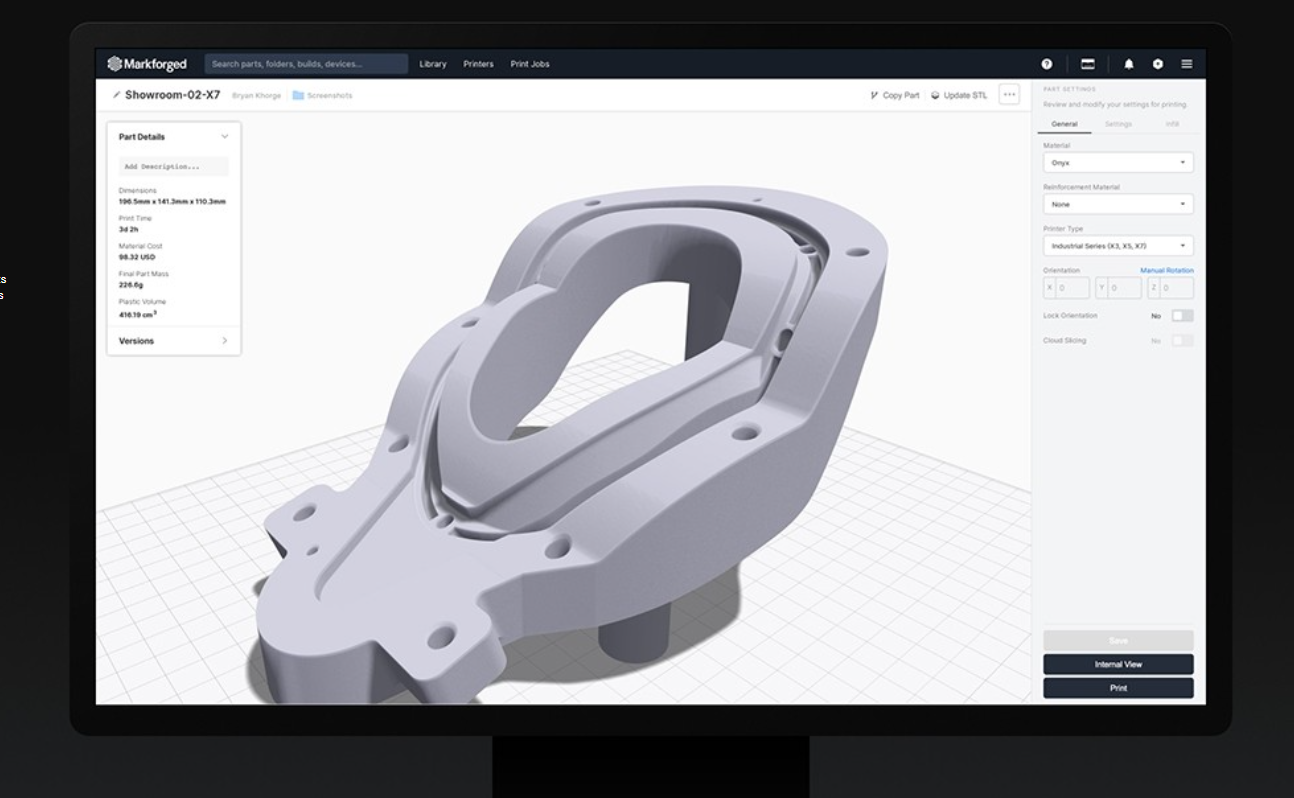

Eiger Cloud– Design, Slice, and Print Directly From Your Browser

3D Printing Software Meets Production Management

Simulate & Inspect- Optimize Part Performance and get Reporting

Speak With an Expert!

Fill out this our quick contact form or call us today- (888) 696-7226

Metal X System

- Reduced Part Weight and Cost

- Functional Parts of All Types

- Industrial Reliability and Accuracy

TECHNICAL SPECIFICATIONS

| Build volume | (300 mm x 220 mm x 180 mm) | |

| Print speed | — mm/s max. | |

| Z Layer Resolution | 100 μm default, 50 μm minimum, 250 µm maximum | |

| Printing Process | Metal FFF & Bound Powder Filament | |

| Nozzle Temp | Max — | |

| Print Bed Temp | Max. — | |

| Metals Available | 17-4PH Stainless Steel, Copper, H13 Tool Steel, Inconel 625, A2 and D2 Tool Steel | |

| Release Material | Ceramic (consumed at 1:10 ratio to metal spools, on average) | |

| Size & Weight | 575 mm x 467 mm x 1120 mm , 165 lbs | |

| Power | 100–120 / 200-240 VAC (12A / 6A), IEC 60320 type C20 | |

| Software | Eiger Cloud(Included), Security, Blacksmith(Additional Purchase) | |