Industrial Additive Manufacturing, Scaled to Your Production Needs

Titanium, Stainless Steel (316L), Aluminum, and Copper Alloys

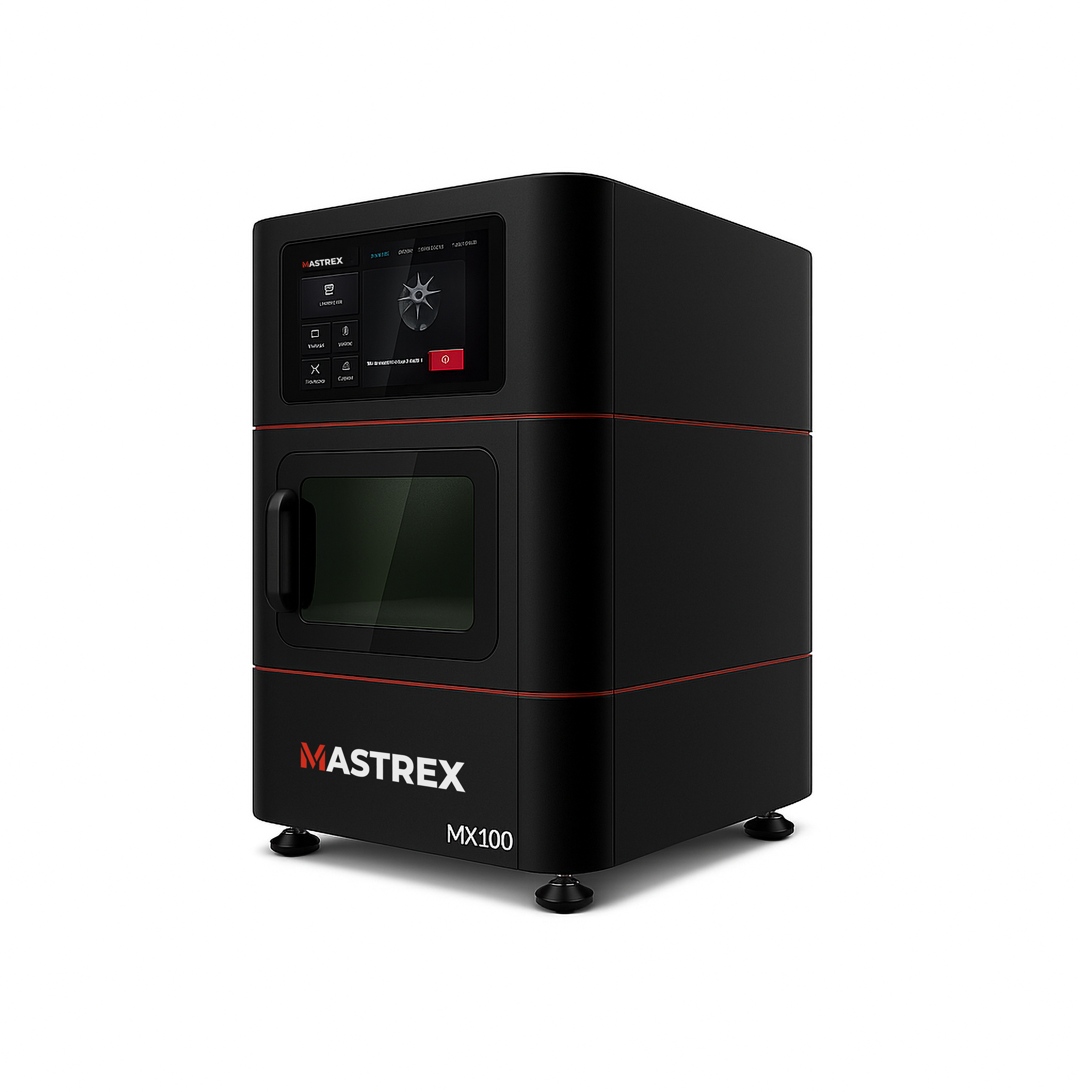

MX100

MX120

MX150

Best for:

Functional prototyping, tooling inserts, fixtures, low-volume production parts

Build Size

-

~300 × 300 × 300 mm

Core Capabilities

-

High-precision motion system for tight tolerances

-

Optimized thermal management for consistent layer bonding

-

Engineering-grade thermoplastics support

-

Fast setup and minimal footprint for labs and production floors

Advantages

-

Ideal entry point into industrial additive manufacturing

-

Lower operating costs with professional-level performance

-

Perfect for R&D teams, product developers, and design validation

-

Reliable repeatability for short-run production

Best for:

Larger functional parts, jigs & fixtures, batch production

Build Size

-

~400 × 400 × 400 mm

Core Capabilities

-

Increased build volume without sacrificing accuracy

-

Enhanced extrusion and material control for longer prints

-

Supports a wider range of high-performance materials

-

Optimized for multi-part batch runs

Advantages

-

More parts per build = higher productivity

-

Ideal balance of size, speed, and cost

-

Scales seamlessly from prototyping into production

-

Strong choice for manufacturing environments

Best for:

Large end-use parts, enclosures, housings, tooling, and production runs

Build Size

-

~600 × 600 × 600 mm (large-format class)

Core Capabilities

-

True large-format additive manufacturing

-

Industrial-grade thermal stability for long-duration prints

-

Designed for structural, load-bearing components

-

Production-ready reliability for continuous operation

Advantages

-

Enables printing parts previously requiring assembly

-

Reduces tooling and mold dependency

-

Ideal for aerospace, automotive, industrial equipment, and defense

-

Maximizes ROI for large, complex components

Designed for precision metal part manufacturing.

Why Choose Mastrex?

-

Industrial reliability and accuracy

-

Scalable platform—from lab to factory floor

-

Engineered for functional, real-world applications

-

Reduced lead times and production costs

-

Designed for continuous, professional use