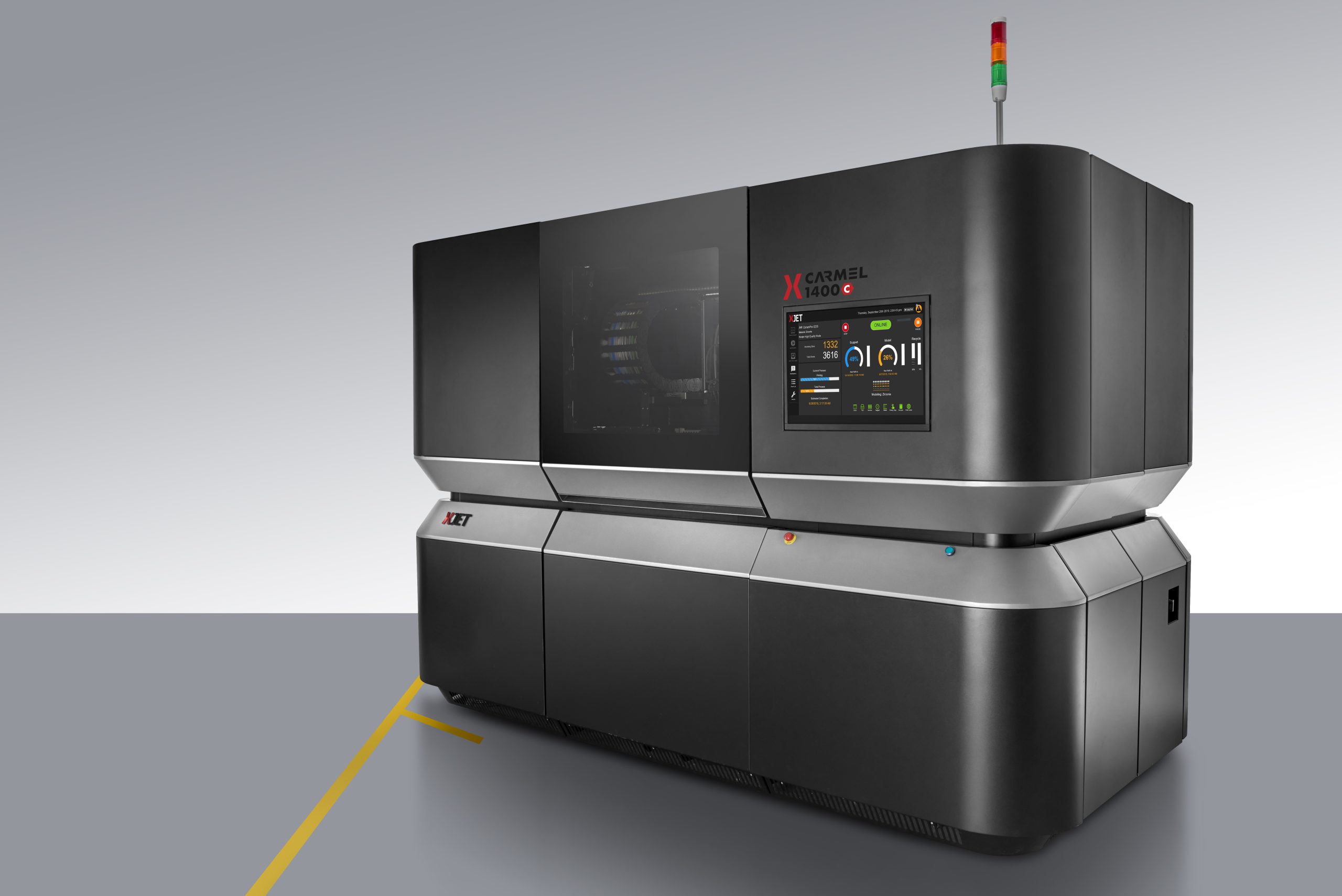

CARMEL 1400C CERAMIC SYSTEM

The industry’s ultimate ceramic AM system for applications requiring high productivity, superior quality and geometric complexity. – ONE OF THE INDUSTRIES LARGEST BUILD SIZES

► Technology Recirculation advanced Inkjet technology

► Build Size 700 cm² (108 in²) build tray – enables the simultaneous production of multiple identical or different parts

► Build Process Simultaneous Model and Support printing | Extra thin layers <10Microns | High resolution material jetting printing

► Layer Thickness : Nozzles- Tungsten carbide (0.4mm, 0.6mm) or polycrystalline diamond (1.0mm)

► Automated, Safe, and Easy Handsfree, unattended operation | Fast turn between jobs | Easy tray loading and unloading

DIRECT MATERIAL JETTING

NPJ TECHNOLOGY

NPJ technology was developed over several years, backed by a portfolio of more than 80 patents and patent applications. Designed with a clear vision, this innovation delivers a digital, direct material jetting process for metal and ceramic additive manufacturing.

By utilizing a specially formulated dispersion ink instead of loose powder, NPJ overcomes many of the limitations and challenges associated with traditional powder-based AM, enabling superior precision, efficiency, and material performance.

FEATURES

NANO PARTICLES INK

ENABLING DIRECT JETTING

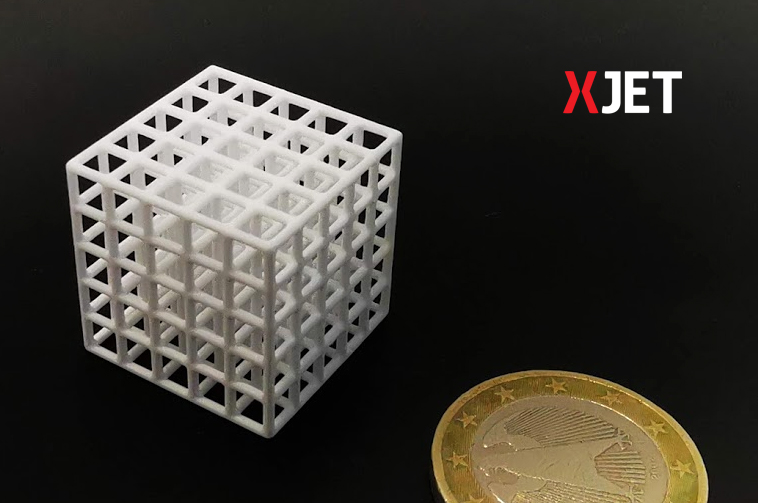

SOLUBLE SUPPORT

ENABLES HIGHLY COMPLEX GEOMETRIES

HIGHRESOLUTION PRINTING

INDUSTRIAL INKJET ARCHITECTURE, ENABLING HIGH RESOLUTION PRINTING AT SCALE

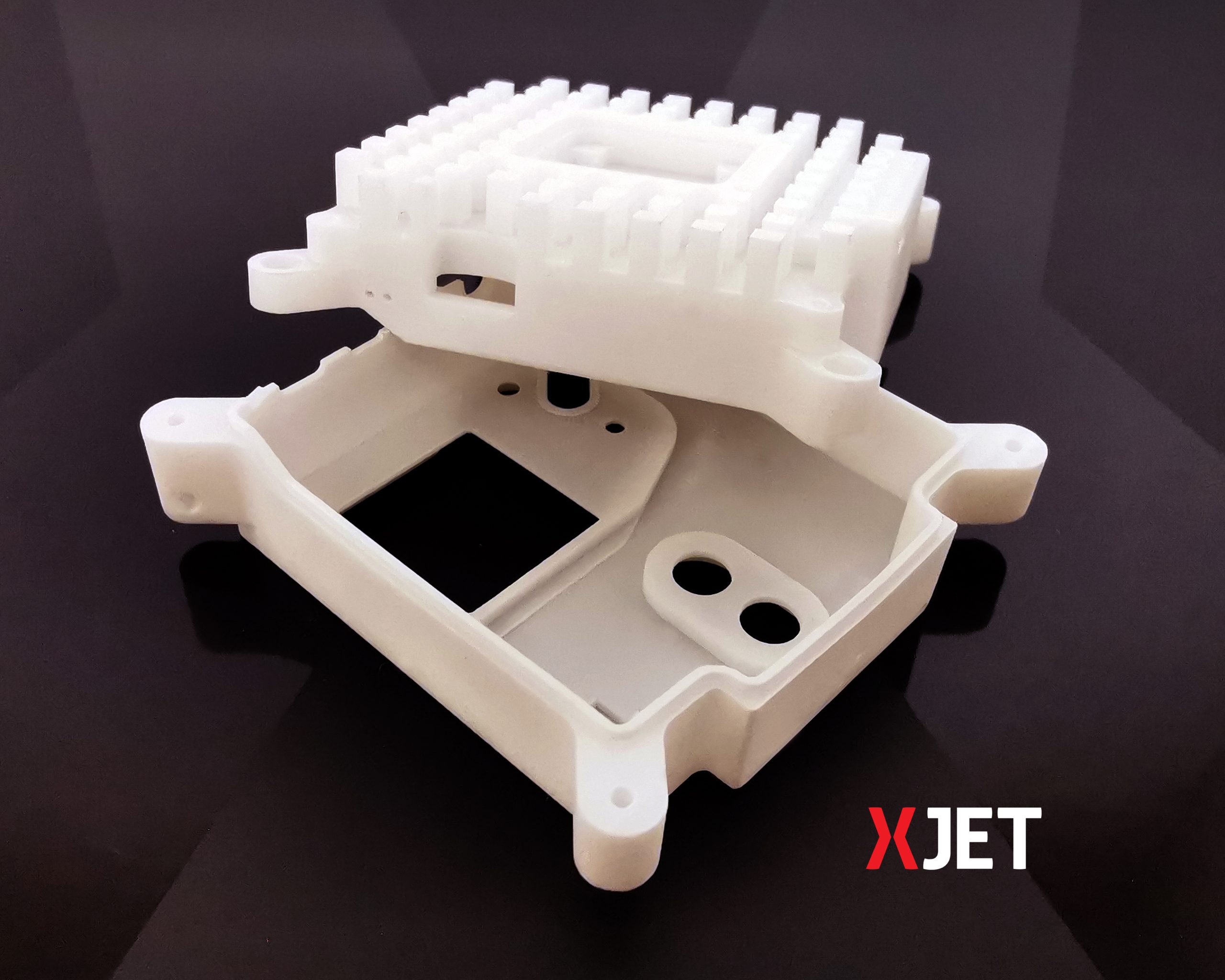

HIGH-QUALITY END-USE PARTS

WITH NO POST MACHINING REQUIRED

Quality

Highly suitable for a wide range of creative ceramic AM applications in diverse industries, due its superior quality and geometric complexity

Accuracy

A patented inkjet technology enables the production of ceramic AM parts of the highest detailing, finish and accuracy

Applications

High productivity & repeatability enabling solutions from prototyping to full fledge manufacturing.

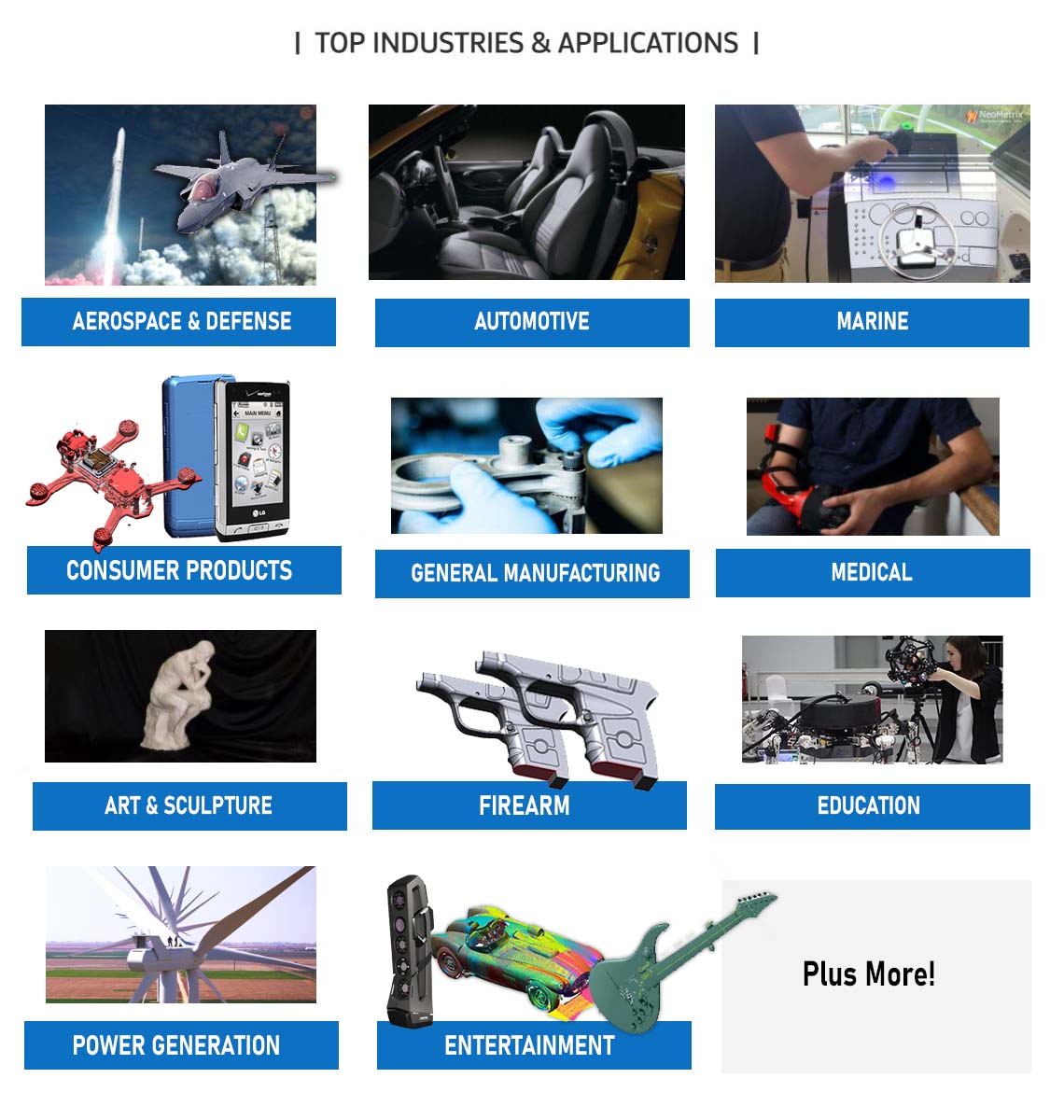

Addressing a broad range of applications from industries such as semiconductors, biotechnology, healthcare, aerospace, automotive, telecom and more

Speak With an Expert!

XJET 1400C

BRING THE FUTURE OF CERAMIC MANUFACTURING TO YOUR BUSINESS TODAY

✔ Unmatched Precision – Achieve ultra-fine details and complex geometries with nano-particle jetting technology.

✔ Superior Material Properties – Produce high-strength, high-performance ceramic parts with industry-leading density.

✔ Streamlined Manufacturing – Eliminate tooling, reduce waste, and accelerate production timelines.

✔ Versatile Applications – Ideal for aerospace, medical, electronics, and industrial components.

✔ Seamless Integration – Easy adoption with expert training and ongoing support.