Industrial Quality meets Cost Efficiency- Complex Parts in Large Scale

The BigRep PRO has set a new standard for the industry. Our next generation of printers are now built with a state-of-the-art Bosch CNC system, enclosed build chambers, and MXT® technology. Engineering-grade materials, now possible on the BigRep PRO, extend the possible applications for large-scale 3D printing—once a major barrier in industrial AM

► Large build volume (1020 mm x 970 mm x 985 mm)

► Print speed- Max. 600 mm/s | Max. 5000 mm/s²

► Fiber-Ready PRO ACE Extruder, ACE is a direct drive extruder, perfectly equipped for fiber-reinforced materials such as BigRep’s HI-TEMP CF

►Next Level Industrial 3D Printer – Built for productivity throughout all stages of manufacturing, the PRO provides designers, engineers, and manufacturers with an easy-to-use, agile solution to produce faster and cheaper.

FEATURES

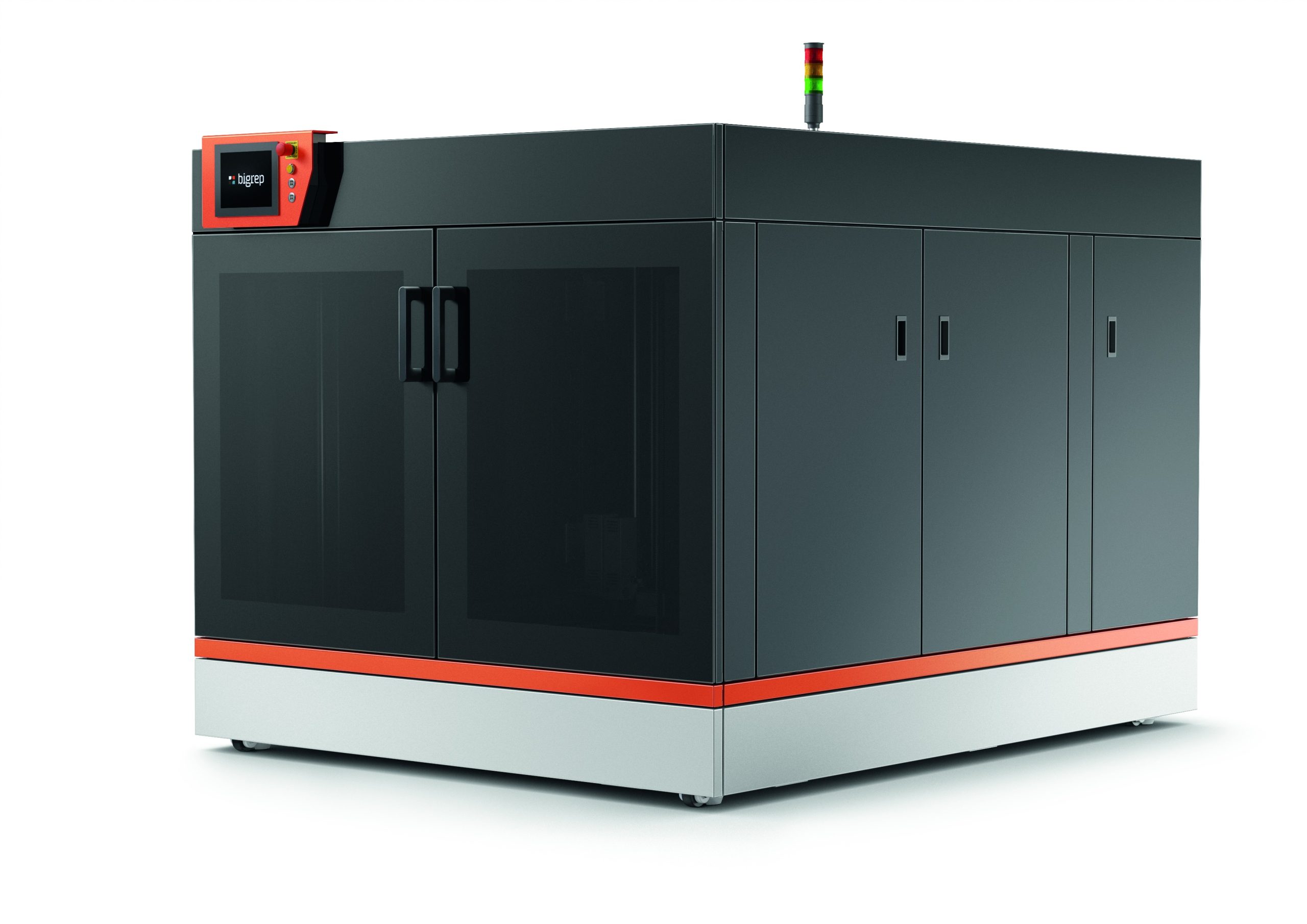

High Accuracy at High Speeds

The Precision Motions Portal

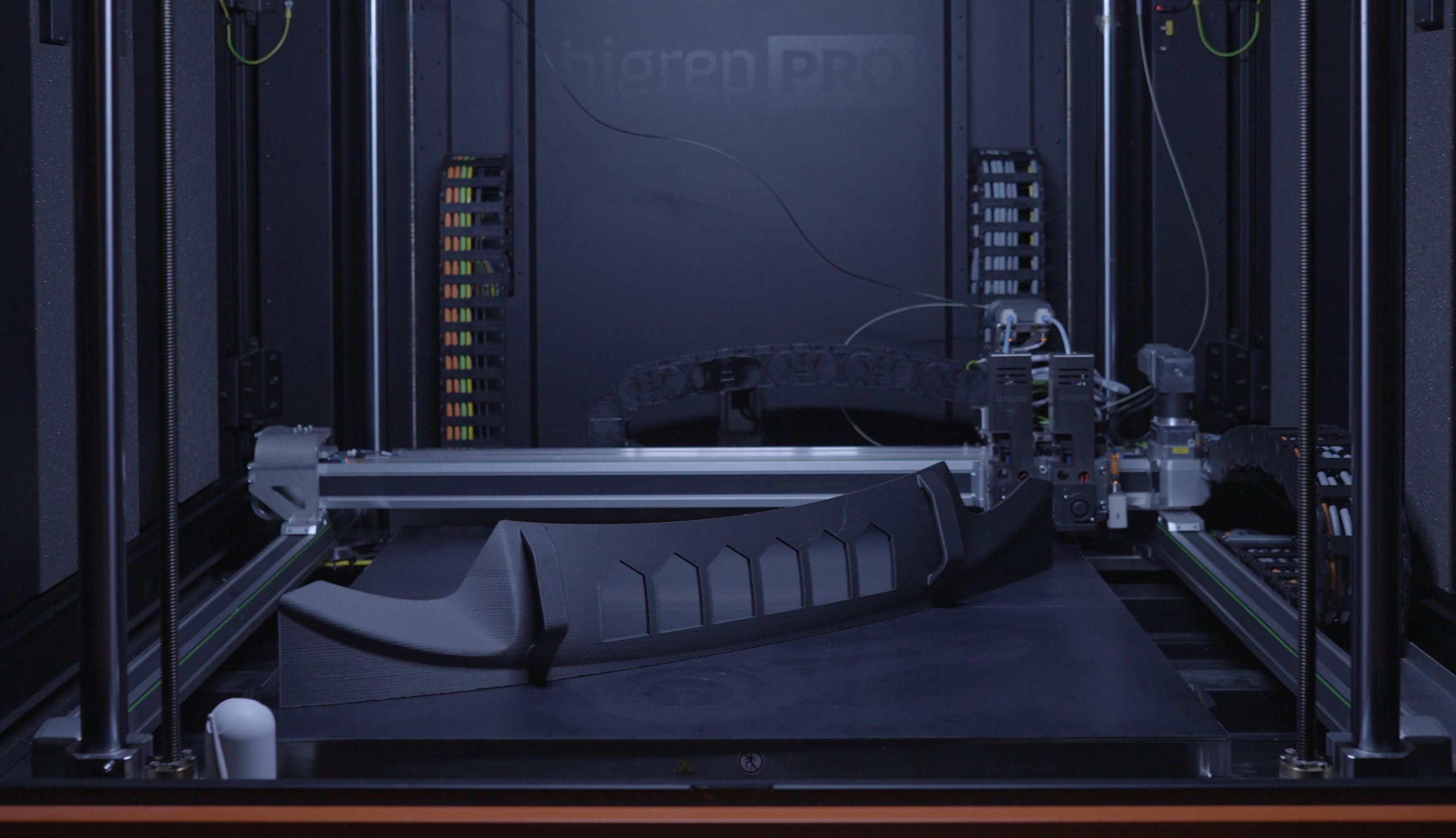

The PRO’s massive 1m3 build volume is supported by a durable, custom-built gantry engineered for high speed, fast acceleration, and accuracy. The robust frame eliminates vibrations during 3D printing assuring fast, yet precise movement gliding the extruders along a reinforced carriage system.

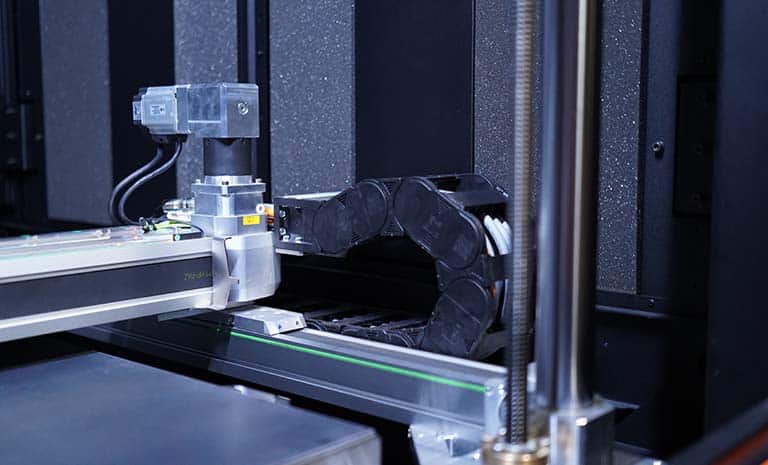

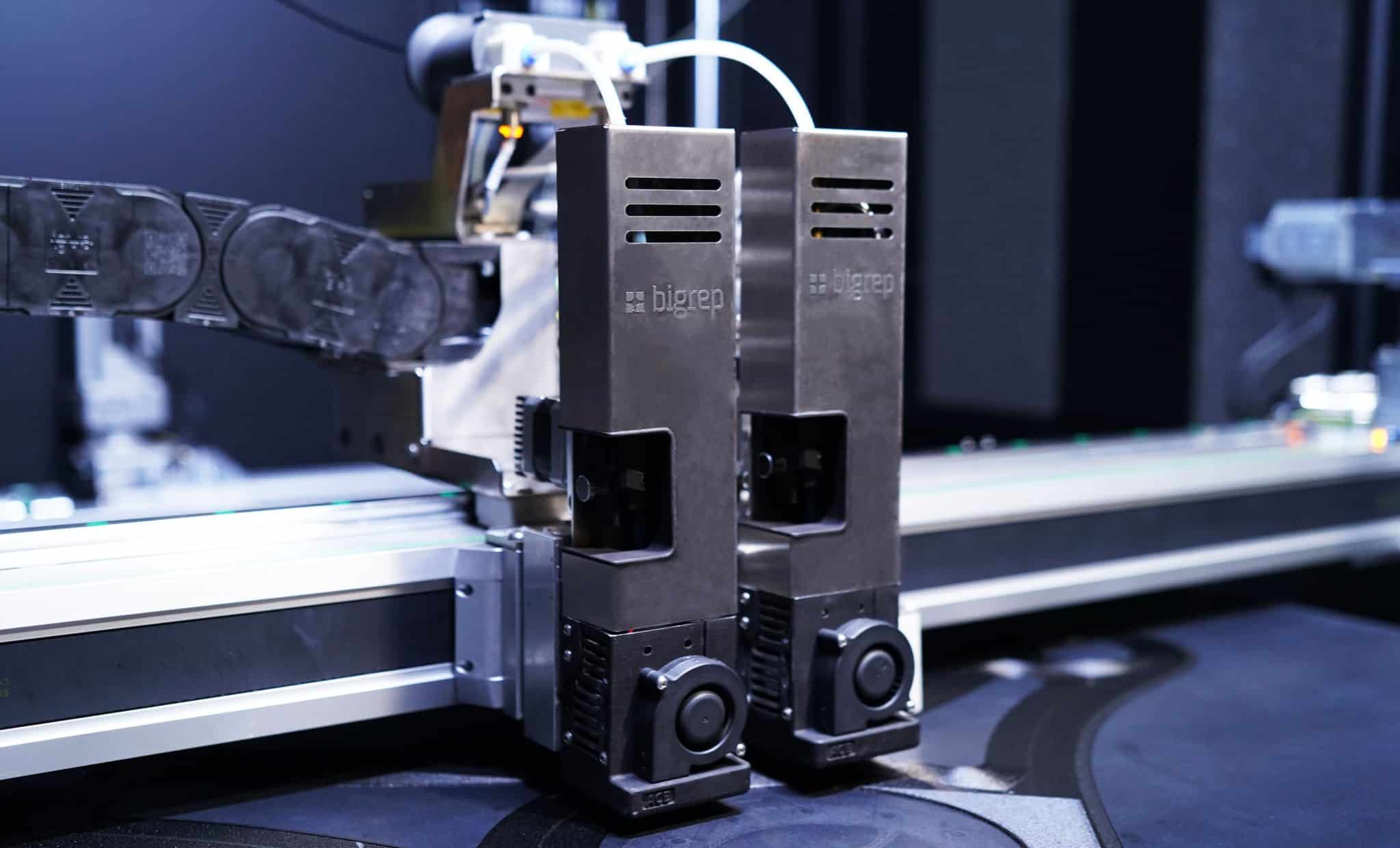

Fast, Precise & Fiber-Ready

The Advanced Capability Extruder

BigRep’s Advanced Capability Extruder (ACE) expands the material capabilities of the PRO while still reliably delivering quality 3D prints with speed and precision. With ACE you can print large-format, strong parts 50% faster than other large-scale printers.

Removable and Flexible Print Bed Surface

SWITCHPLATE®

Removable and flexible print bed surface available in different coatings, each optimized for various materials ensuring proper bed adhesion. It is magnetic and easily snaps into place. Heat increases the adhesiveness of the surface so your print stays fixed during printing, but is easy to remove once cooled.

Airtight Filament Chamber

The Dry Material Storage

The PRO’s environmentally sealed filament chamber with a two-spool capacity ensures that all materials, including engineering-grade and water-soluble, remain dry in a consistently temperature and humidity-controlled environment.

BigRep PRO Video

Helicopter Blade Cradle

Includes:

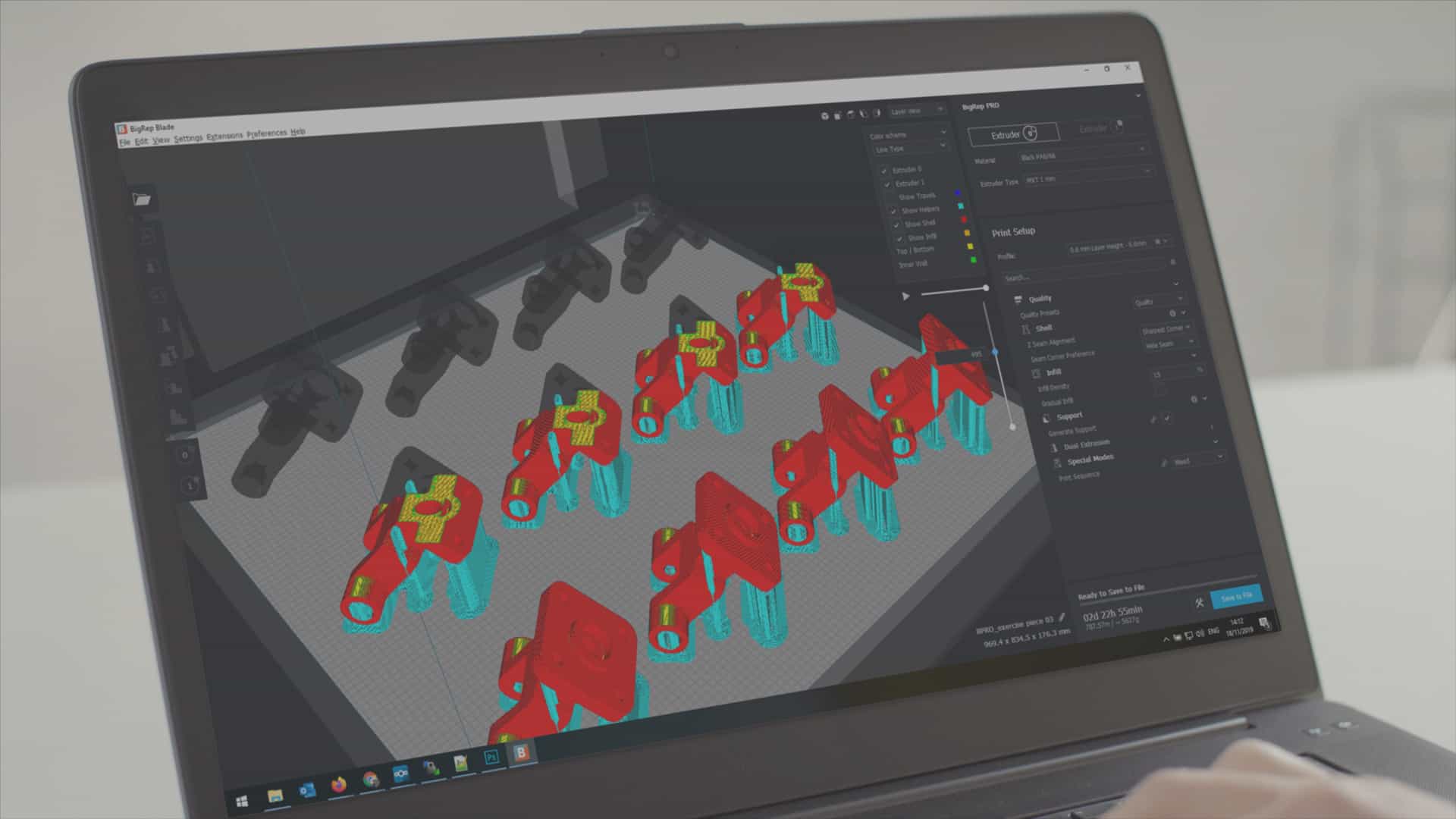

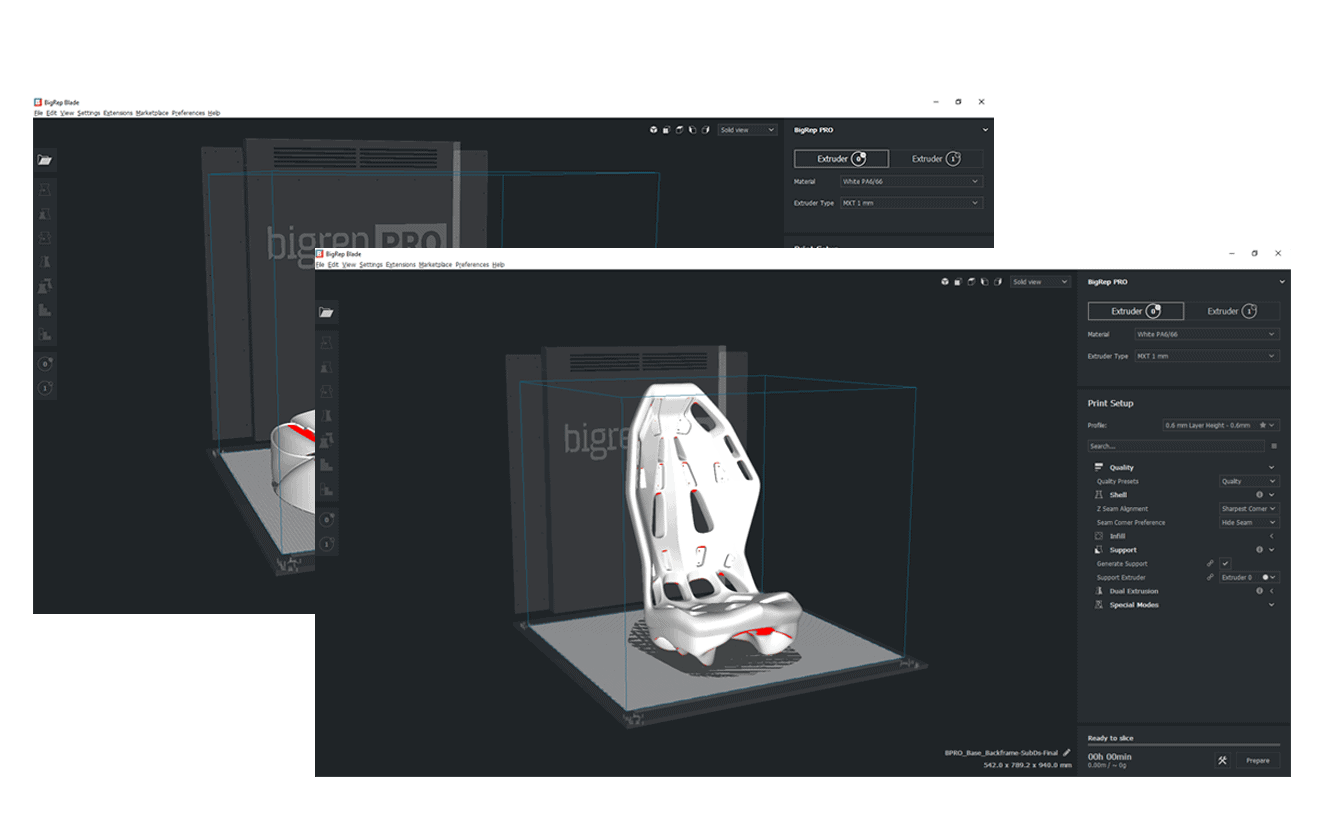

A SMART 3D SLICER FOR INDUSTRIAL APPLICATIONS

Speak With an Expert!

Fill out this our quick contact form or call us today- (888) 696-7226

BigRep PRO

JUMPSTART. SKIP THE HASSLE. JUST PRINT.

-

-

-

3D Print in Full Scale

-

Boost Productivity

-

Cut Your Costs

-

Print Parts in a Variety of Engineering Grade Materials

-

-

TECHNICAL SPECIFICATIONS

| Version | BigRep PRO.2 | |

| Build volume | (1020 mm x 970 mm x 985 mm) | |

| Print speed | Max. 600 mm/s | Max. 5000 mm/s² | |

| Layer height | 0.3 mm, 0.6 mm | |

| Extruder | Fiber-Ready PRO ACE Extruder | |

| Nozzle Diameter | 0.6 mm, 1.0 mm | |

| Nozzle Temperature | 280°C max. | |

| Printing technology | FFF- Fused-Filament-Fabrication (FDM) | |

| Certified materials | BigRep PLA, BigRep HI-TEMP, BigRep HI-TEMP CF, BigRep PRO HT, BigRep PETG, BigRep ASA, BigRep PA6/66, BigRep PA12 CF Water Soluble BigRep BVOH Open for use of 3rd party materials |

|

| Build Volume Temperature | 40°C max. | |

| Printer weight | Approx. 2160 kg (4762 lbs) | |

| Size | x 1950 y 2500 z 2105 mm / x 77 y 98 z 83 inches (with tower) | |

| Power | 3 Phase 400V AC, PE, 16 A, 50 / 60 Hz | |

| Safety Certifications | UL, CE, EC Machinery Directive 2006/42/EC Compliant | |

| GUI | Onboard with multi touch panel | |

| File transfer | USB & remotely | |